Laboratory and Cleanroom Accessories

Cabinets & Carts: ALLpaQ Innovation for your Cleanroom

Introducing the 2D Transfer Cabinet Picture this: You need a storage solution for a specific spot in your cleanroom, but […]

Apr 22nd, 2024

Cabinets & Carts: ALLpaQ Innovation for your Cleanroom

Apr 22nd, 2024

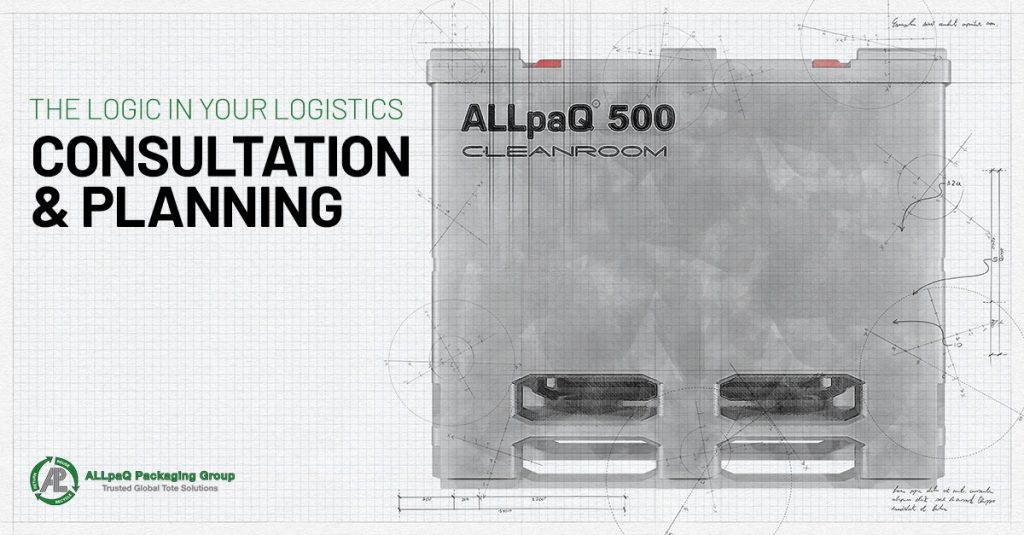

At ALLpaQ, our state of the art bioprocess products are made-to-measure! And, how do we measure success? Well, we gauge our success against the happiness of our clients. After all, happy clients are regular clients.

You can count on ALLpaQ Packaging for reliable, customised secondary packaging that safeguards your valuable liquids throughout the entire bioprocessing journey.

ALLpaQ Packaging specialises in creating made-to-measure custom rigid plastic boxes (bioprocess totes) designed to accommodate a variety of single-use bag types, ensuring secure shipping and handling.

Our experience and expertise allows you to enhance your process by deploying our made-to-measure rigid liquid packaging.

We design and fabricate custom modifications to meet your specific needs. We can do this in a wide range of different ways, for example …

1: Your Bag & Your Process

Tailoring unit modifications to accommodate the validated bag you already use and your process requirements.

2: Shape & Size

We can adapt the shapes and sizes of our products to perfectly suit your individual preferences and specifications.

3: Bag Port Positions

We can align bag port positions with your existing validated 2D and 3D single-use bags, for seamless filling, draining, and processing.

4: Drop Doors & Dynamic Doors

Many of our products include drop doors for easy access and handling, or dynamic doors which do away with bug-trap hinges. These can be transparent for added visibility.

From upstream to downstream bioprocessing, reliable secondary liquid packaging is essential to safeguard your valuable fluid media. If your existing bag is already validated, ALLpaQ offers a diverse selection of non-standard shipping, warehousing, and cleanroom tote options which are compatible with all bag types available in the market.

In the event that your chosen bag’s dimensions are not supported by our extensive standard range of products, our team of specialised bioprocess and fabrication engineers and architects is ready to create a tailored solution just for you.

With almost 20 years’ experience producing made-to-measure products to clients’ specifications, we understand the criticality of securing precise secondary packaging that complements your primary packaging. Leaving excess space in the secondary biocontainer packaging after bag filling can increase the risk of splitting and leakage caused by bag movement.

Also, we know that time is of the essence, which is why we, at ALLpaQ, have streamlined our workflow to ensure swift development of your custom secondary packaging solution, all perfectly primed to support your primary packaging needs.

When it comes to your specific bag dimensions, ALLpaQ has you covered. Our team of bioprocess and fabrication experts is ready to provide tailored made-to-measure solutions that align perfectly with your requirements. Whether you need shipping, warehousing, or cleanroom totes, we offer a wide range of options compatible with all bags available in the market.

Here’s how we make it happen:

Experience the power of made-to-measure solutions with ALLpaQ Packaging, where your unique needs are at the forefront of every step we take towards your bioprocess success.

We continuously seek opportunities to identify and implement improvements to our products, so we can continue to enhance and optimise your fluid management processes.

Therefore, if you have a made-to-measure challenge for us; if you think your bioprocess conundrum is beyond the abilities of any 2D and 3D Bag Handling Accessories supplier – get in touch. Let’s talk!