Pharmaceutical Industry News

Downstream vs upstream processing

Upstream and downstream processing work in tandem to produce desirable products, such as beneficial pharmaceuticals like medicines or biochemicals. But […]

Oct 21st, 2025

The pharmaceutical supply chain is essential for ensuring that research facilities and healthcare providers receive the correct quantity of products they need on time and in quality condition.

However, the entire process can be surprisingly complex and has its challenges.

Throughout this article, we’ll explore the biggest potential problems in the pharmaceutical supply chain and why ALLpaQ bioprocessing containers are the ideal option for moving pharmaceuticals and their related materials.

Pharmaceutical transportation refers to the movement and carrying of medical goods and their related materials, such as fluid media for bioprocessing. It may include distribution via road, sea, or even air.

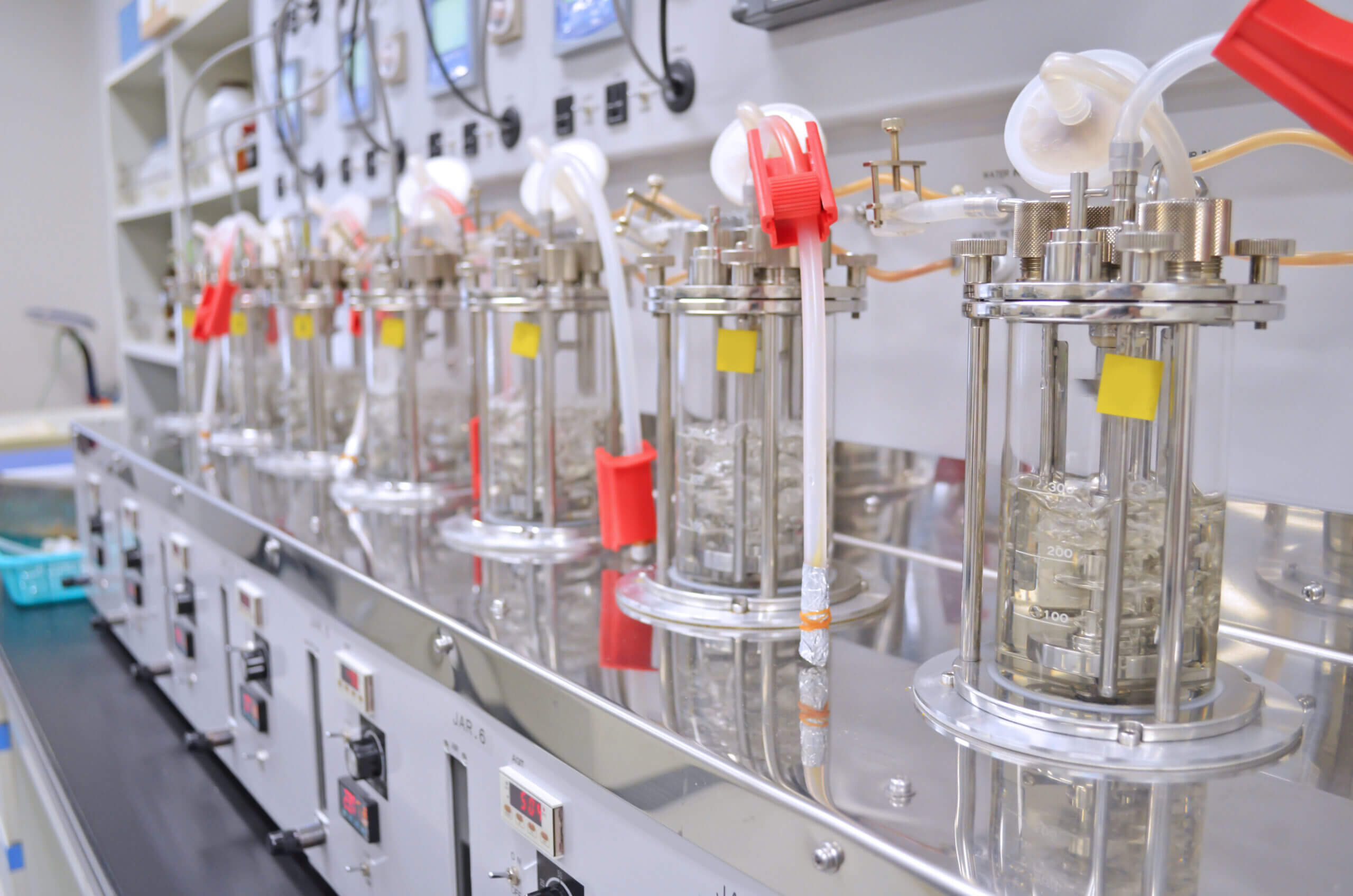

Flexible film technologies, stainless steel models, or sturdy hard plastic bioprocess containers are utilised by pharmaceutical companies to store the media they intend to transport.

The distribution of pharma products must be managed carefully to prevent gaps in the supply chain, but what needs to be considered when transporting medical goods?

For your business, it’s imperative to follow Good Distribution Practice (GDP) when it comes to the storage and transportation of your pharmaceutical goods or their associated bioprocessing fluids.

GDP implementation is overseen in the UK primarily by the Medicines & Healthcare Products Regulatory Agency (MHRA).

The fundamentals of GDP include:

You may also want to consider traceability to ensure your logistical processes are trustworthy and use reusable packaging solutions to improve your company’s commitment to sustainability.

An effective and organised supply chain, modern technology, and reliable handling systems, such as bioprocess containers, will help you comply with GDP and enhance your pharmaceutical transit practices.bioprocess containers, will help you comply with GDP and enhance your pharmaceutical transit practices.

Storing biological substances, buffer solutions, or final drug products in sterile and robust bioprocess containers from ALLpaQ can elevate your logistic processes.

A cutting-edge alternative to steel or rigid types, ALLpaQ containers are reusable apparatuses that shield media bags from impacts and damage and help to maintain a sterile storage environment throughout the logistics cycle.

Our containers are developed by our specialist technical team equipped with the expertise to deliver exceptional bioprocessing containers designed to enhance your transport operations.

But what makes our bioprocess containers stand out from the rest? Let’s take a look.

ALLpaQ shipping containers have many air pockets within the wall construction providing excellent insulation characteristics to assist with temperature-controlled distribution.

Being an ISO 9001-certified company, you never have to worry about the quality of our fluid management systems.

Thanks to expert plastic welding, you can also rely on our containers to protect your valuable pharma solutions during storage or transportation – plus, you should also know that our Genesis containers are ISTA-tested and validated.

This way, you can relax knowing the chances of leaks and cross-contamination are greatly reduced and valuable fluid media won’t go to waste, preventing additional costs.

We can also create and fabricate custom containers per your unique needs – from custom sizing to company branding, we’ve got you covered.

To make logistic procedures more efficient, we’ve created a series of user-friendly and ergonomic bioprocess containers.

Our units are collapsable, meaning they can be easily folded away after use, helping to free up warehouse space and reduce return transport space/cost. What’s more, each features a palleted base to make storage and transportation more stable and container retrieval simpler.

Wave goodbye to repeat orders of single-use containers and hello to reusable bioprocess containers. ALLpaQ products can be kept in rotation for many years, making them a highly economical investment.

Plus, after they’ve completed their lifespan, they can be recycled and used in future developments. Taking you one step closer to a sustainable future!

Our reusable bioprocess containers are manufactured from strong yet lightweight poly plastics, which makes handling hassle-free and reduces shipping costs and carbon emissions.

This differs immensely from heavy stainless steel models that are much more difficult (and expensive) to manoeuvre and ship.

Boost the cleanliness of your operations with our unique container units.

ALLpaQ’s innovative designs can be jet washed and include smooth and removable panels that are simple to disinfect – inhibiting bacterial growth.

With our range, you never have to worry about losing your bioprocessing liquids during transit thanks to smart GPS/GSM tracking.

Remote tracking provides you and your team with insights into where your containers are and how many are in operation – they also alert you when your container is empty and ready for collection.

Now is the time to replace your single-use packaging and upgrade to reusable plastic units from ALLpaQ.

We’re established manufacturers of bioprocess containers and our products are chosen by clients and partners across the globe to modernise their laboratory processes.

If you would like more details regarding our product range or want to speak to our experts about placing a custom order, contact a member of our team online or call us on 01472 800 373.