Company News

Meet ALLpaQ’s Business Development Managers

At ALLpaQ, we understand that the greatest resource of any successful business is its people, and we’re excited to welcome […]

Jul 16th, 2024

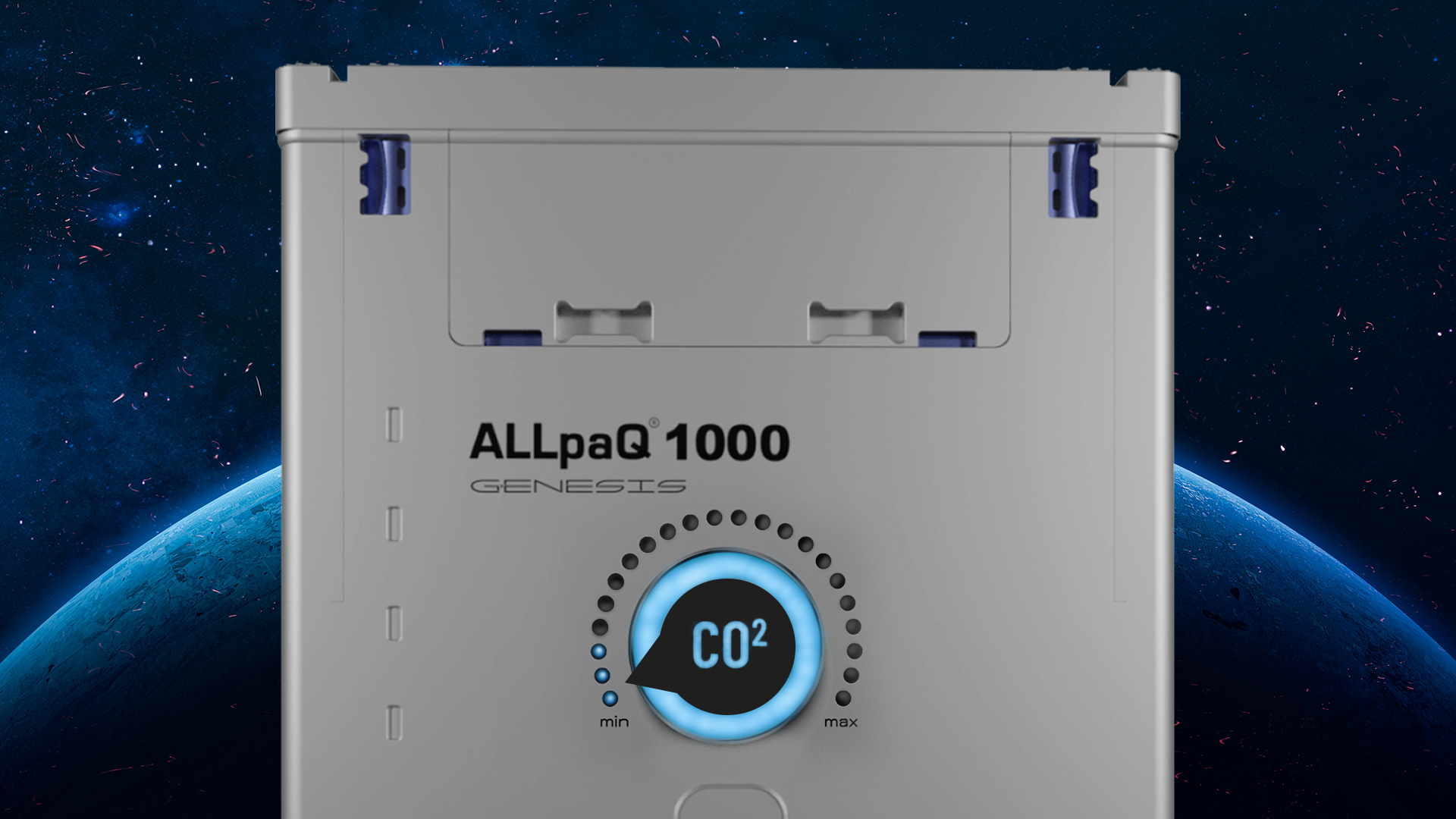

Bioprocess containers from ALLpaQ are designed to help businesses manufacture, store, ship and protect valuable media, buffers and bioprocess liquids. Our bioprocess containers are also designed to help reduce businesses running costs and carbon footprints.

That’s because, at ALLpaQ, we believe environmental and financial sustainability should go hand-in-hand. It is a mantra that is fabricated into the very DNA of our fluid management products.

And it is great to see this fiscal and environmental prudence reflected back in the pharmaceutical, life science and biotechnology companies we work with. No longer is it simply about finding the right bioprocess secondary packaging to fit the bag, it’s about creating an optimal fluid management process.

Industry has made huge strides in reducing collective and individual carbon footprints. This is to be celebrated. But, this should also be prefixed with the understanding that more should and can be done.

After all, it is an issue that affects us all, as we all share the same world.

So let’s take a look at some of the ways ALLpaQ bioprocess containers can help you cut costs and your carbon footprint.

When it comes to bioprocess containers, managers in the biopharmaceutical industries have traditionally faced a choice between plastic and steel secondary packaging.

Today, the plastic bioprocess container revolution is upon us. And there’s a number of reasons why they are making the switch to ALLpaQ:

Freight is a necessity for many businesses which operate on a global scale. Whether it’s by air, sea or land, it can all add up in terms of cost and the environmental impact. Air freight, in particular, can be extremely taxing on a business’ economy and carbon footprint.

One of the main factors which makes it costly is both the size of the item, but also the weight. Both inevitably burn more fuel on an aircraft, therefore increasing cost as well as carbon emissions.

If you are looking to transport your biochemical material in the first place this in itself will weigh a significant amount. However, add in extremely heavy totes, such as those made out of steel, and you are also likely to amass a huge expense not to mention huge carbon footprint.

Whilst some companies might just accept this is all part-and-parcel of transporting goods thousands of miles around the globe, what if there was another way to save both cost and emissions?

ALLPaQ containers are a lightweight, plastic equivalent of their steel counterparts. The containers are foldable, stackable and compatible with most 3D bags, which in themselves are lighter, cheaper and greener to use.

Not only is this cost effective for your business, but it’s also much greener for the planet, as less weight equals less fuel burned by the aircraft.

Plus, once folded up, the empty containers take less room in the vehicle, which means fewer vehicles are needed to bring your totes back home – offering a further fuel saving.

This means less of an impact on the environment, something which all companies – especially those who operate on a global scale – have a responsibility to reduce wherever possible.

Additionally, purchases of select ALLpaQ containers contribute to our partnership with B1G1, which ensures that trees are planted around the world – making a very real long-term impact on the environment.

In terms of the wider pharmaceutical supply chain, changing up what has been a fundamental problem for decades has the potential to reduce costs and CO2 emissions in one go. Switching to an ALLpaQ bioprocess container couldn’t be simpler, and will help both your business and the environment too.

After all, reduced weight and a collapsible product will mean less emissions and more space saved. The containers are also temperature controlled and come with the option of GPS tracking, meaning it’s never been easier or greener to manage your freight.

To find out more contact us today on +44 (0) 1472 800 373, email us enquiries@allpaq.com or fill out the form.