Pharmaceutical Industry News

Downstream vs upstream processing

Upstream and downstream processing work in tandem to produce desirable products, such as beneficial pharmaceuticals like medicines or biochemicals. But […]

Oct 21st, 2025

Considering new biopharmaceutical fluid management products for your company, such as bioprocess containers?

The biopharmaceutical field depends heavily on fluid management to enhance their daily workflows and better their medical products.

Keep reading to see what our experts have to say about biopharmaceutical fluid management and how our bioprocess containers can elevate your workflow.

In the bioproduction industry, fluid management, also known as a fluid management system is a series of procedures and equipment used to prepare, handle, and regulate the transfer of liquids around your biopharmaceutical facility.

Fluid management systems help to ensure the control and transfer of essential fluid media – these liquids include but aren’t limited to:

Fluid management greatly impacts the effectiveness of your daily operations – it’s also vital to reduce the risk in your bioprocess in terms of product quality, potency, and safety.

With efficient fluid management, you can prevent contamination and ensure controlled dispensing so your workflow is as cost-effective and precise as possible.

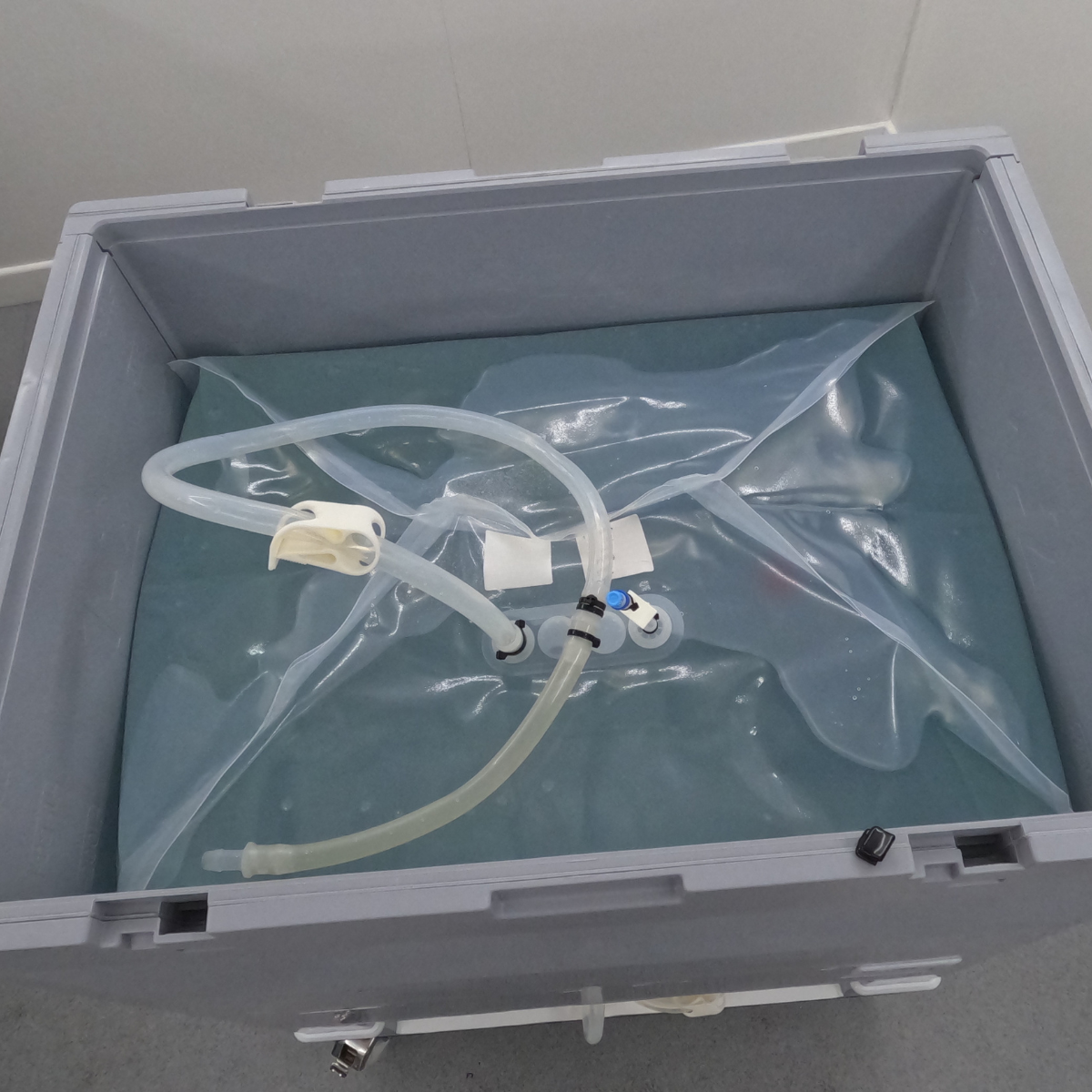

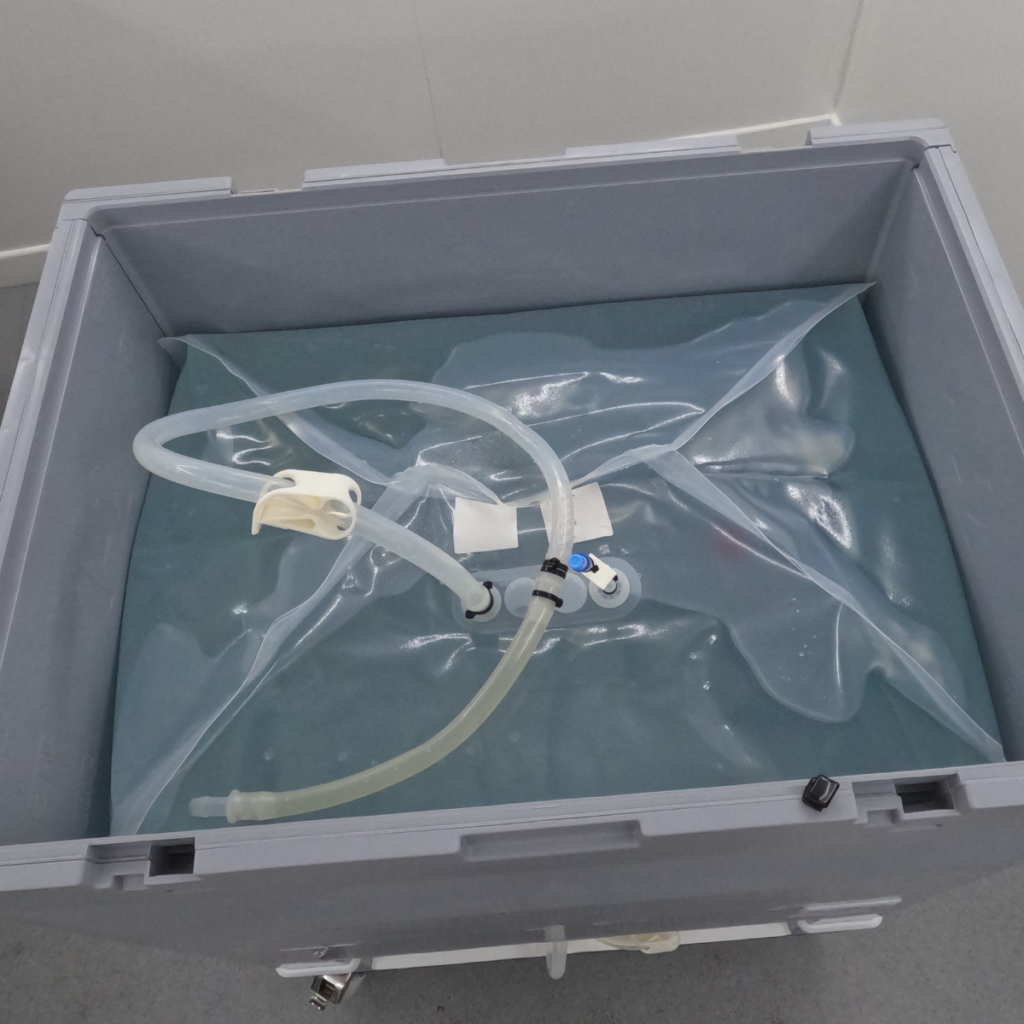

Single-use bioprocess bags are used within the manufacturing workflow due to several factors.

Firstly, equipment within fluid management must possess the necessary mechanical and chemical properties, such as flexibility, durability, and solvent compatibility, to reduce the danger of leakage. Plastic single-use 3D bioprocessing bags boast these properties, making them a great fit for your workflow.

Secondly, these fluid handling bags and their components are used once and discarded, which reduces contamination risks between batches as the fluid track doesn’t need to be sterilised.

However, these bioprocess bags need to be stored safely and correctly – this is where reusable bioprocess containers come in.

Bioprocess containers are secondary packaging units that play a critical role in fluid management systems, helping to safely store and move fluids from A to B.

These sterile and durable bioprocess containers house and protect the single-use bags from becoming contaminated, reducing the likelihood of tears and leakages during transportation and storage.

There are many reasons why you should consider bioprocess containers from ALLpaQ:

We can design and manufacture bespoke containers tailored to your specific requirements, whatever they may be!

Modifications may include shape and sizing, bag port positions for custom filling, draining, and processing, or adding branding. Contact us today for more guidance!

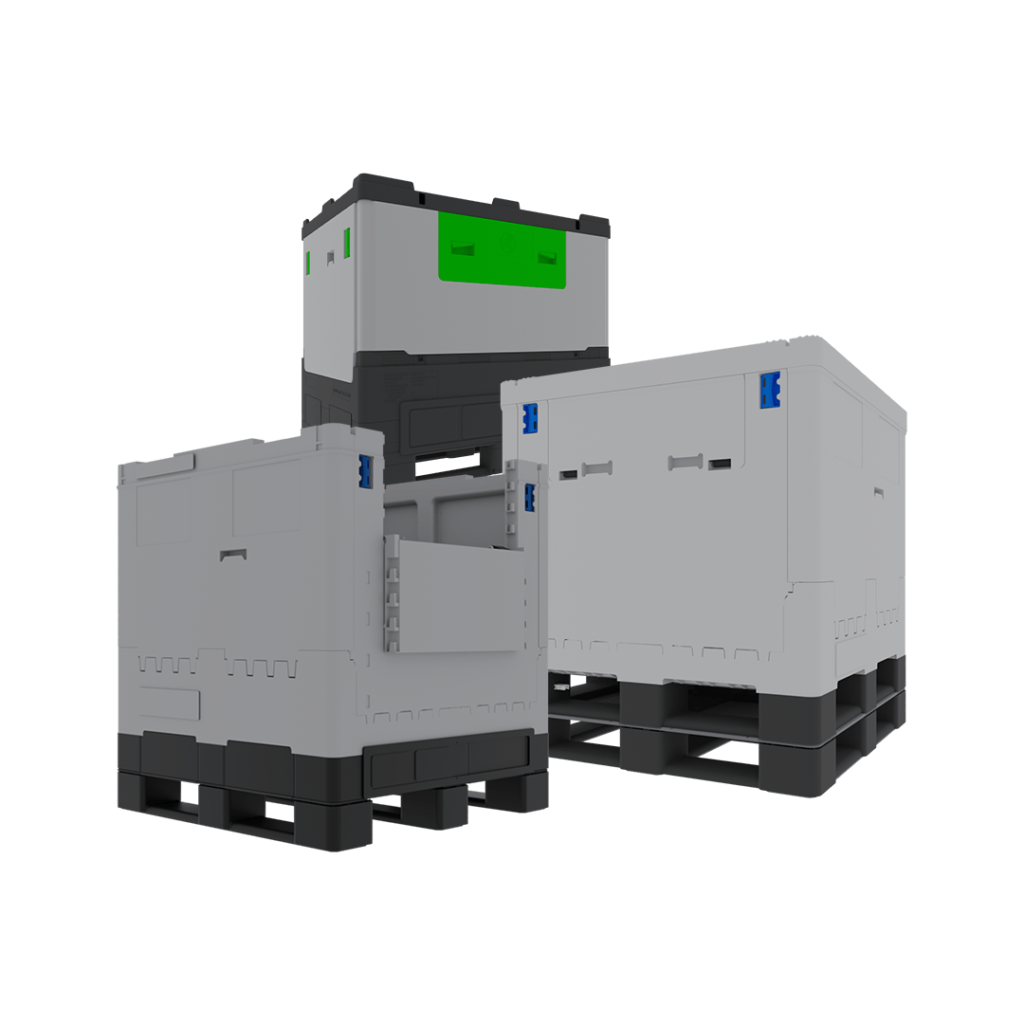

Our ingenious engineers have produced a series of bioprocess containers that combine lightweight plastic construction that boasts improved hardiness and robustness.

So you can relax knowing your fluid management solution will shield your media all while reducing shipping costs and remaining easy to manoeuvre.

Helping to inhibit cross-contamination during fluid transfer applications and storage, our virgin polypropylene units reduce cross-contamination and feature removable smooth wipeable walls that inhibit bacterial growth. Plus, they are jet-washable, making sterilisation easy.

Ergonomic and foldable, ALLpaQ bioprocess containers can be collapsed and folded away, saving valuable space.

They also feature palleted bases for optimised warehouse storage and simplified handling. You can also return multiple units as opposed to half the number out, as they are folded and stacked.

What’s more, our foldable, stackable units can also help reduce transport costs.

Boost your company’s environmental practices by investing in our reusable systems that are recyclable at the end of their long life cycle.

Enhance your processes with our reusable fluid management bioprocess containers.

With multiple certifications, including ISO 9001 and 14001, and accreditations such as EcoVadis Gold, you can be sure you’re investing in an organisation that strives to manage its environmental impact – which only boosts your company’s impact.

To enquire or place an order, please call us on 01472 800 373 or contact us online and we’ll get back to you ASAP.