Company News

Meet ALLpaQ’s Business Development Managers

At ALLpaQ, we understand that the greatest resource of any successful business is its people, and we’re excited to welcome […]

Jul 16th, 2024

Growing up, Willy Wonka’s chocolate factory was the place I wanted to be. Sure, the guy had eaten too much sugar. But the lure of this mad inventor’s edible landscapes more than made up for the fact that he was a little ramped up.

From within the sugary subtext of Roald Dahl’s masterpiece an interesting subtext can be pulled – many of his delights were package-free. Like a ripe tomato, Wonka products could be plucked then directly consumed.

This was somewhat forward thinking of Dahl, portending to today’s food packaging zeitgeist. Some manufacturers, for instance, believe they have discovered the golden ticket to making package-free products a reality in our supermarkets.

But would you purchase a product contained in edible packing? There’s a number of innovative development companies out there who believe, eventually, you will. They say the answer to reducing excess food packaging resides within how nature creates its own biodegradable packaging.

Let’s take the bite sized snack protectors – they are all the talk right now. These products aim to redefine the way we package food with durable, water-resistant edible membranes made from natural food particles. The portion of food is safeguarded within its casing much like the skins of fruits.

Interesting, right?

Perhaps what is more interesting is how the debate taps into the need for sustainable packaging across all industries. In the pharmaceutical sector where we work, for example, sustainability is at the forefront of our packaging design.

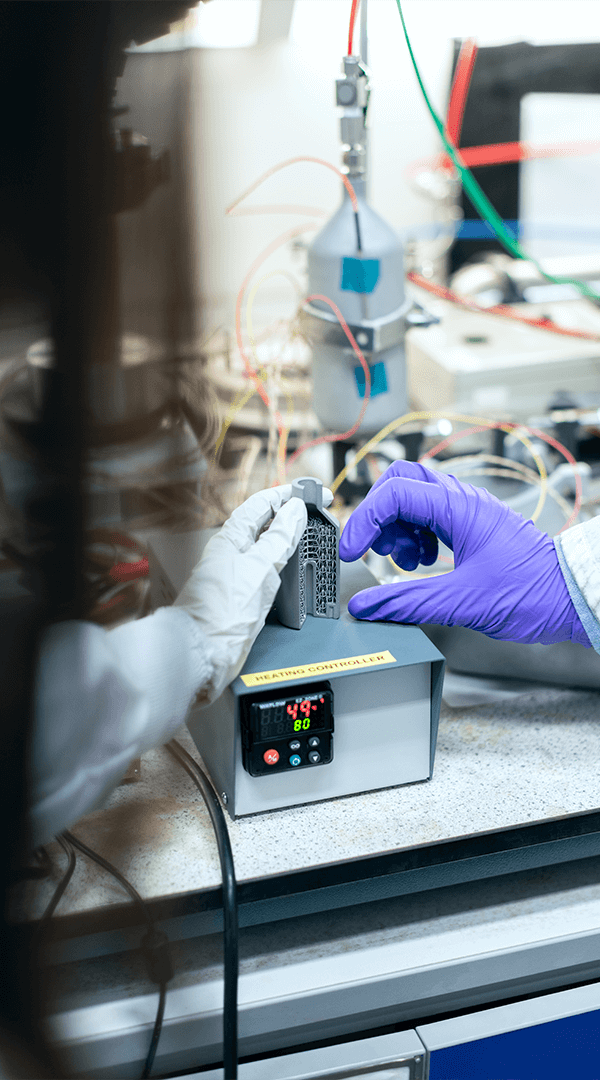

ALLpaQ was, in fact, born out of a desire to rethink the traditional packaging model pharma and life science companies had become accustomed to when transporting valuable fluid media.

Bioprocess containment isn’t going away anytime soon.This is a reality. It remains a part of daily life for most businesses and organisations. Even so, we all have a duty to store and transport media responsibly.

At ALLpaQ then, rather than aiming to eradicate containment packaging, we fabricate designs which streamline their operational capabilities. They are stackable and collapsible, for instance.

This means companies can save space in shipment and massively reduce transport journeys via air, sea and land. It’s a win win for both profits and environmental sustainability.

The bottom line is that, as creators of packaging, we all need to think outside the proverbial box.

Like Willy Wonka with his sugary delights, we need to ask ourselves: “Is there a better way we can do this?” And, if there is, let’s do something about it. Actions always speak louder than words.