Containers Product News

The exciting applications of biotechnology aren’t limited to one singular sector – in fact, a plethora of industries benefit from […]

Jan 14th, 2025

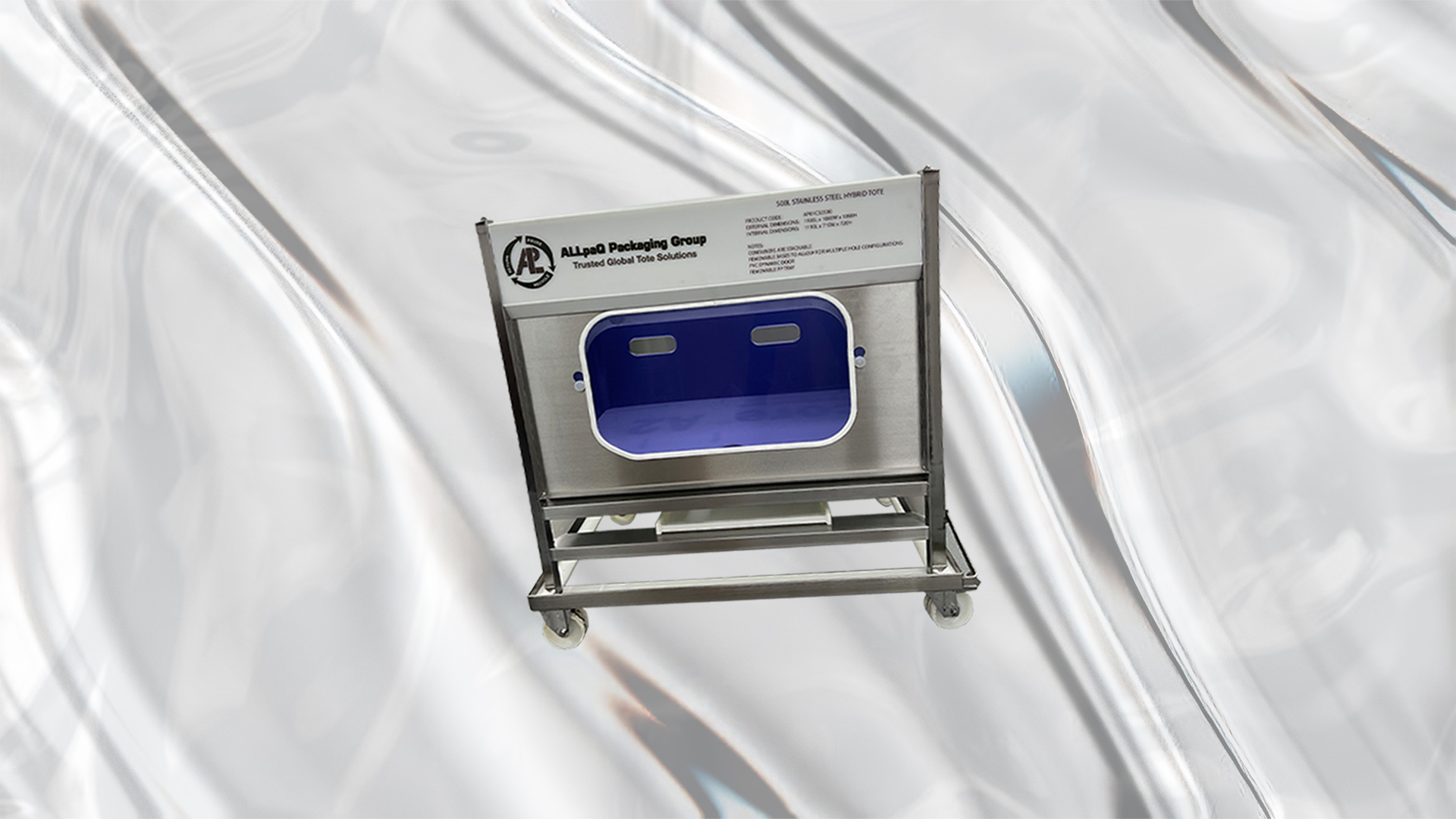

With our new Hybrid Stainless Steel Tote we, at ALLpaQ, have been doing what we do best: Innovation!

There’s no denying that stainless steel has been a market-leader in pharma packaging for many years. However, we were a disruptor in that stainless steel status quo, when we brought plastic bioprocess containers into the marketplace in 2005.

We’ve detailed our 18-year process of innovation and evolution in this article.

Our pioneering work has stimulated a lot of our clients to look at plastic solutions for the first time, and to adapt their workflow to take advantage of the benefits plastic offers. But, we have always been aware that plastic isn’t necessarily the right choice for all businesses.

So, our challenge was to come up with an audacious way to make the most of plastic’s usability and customisability, whilst working in concert with the features of steel containers.

This is why we developed our own stainless steel bioprocess tote solution – and it’s unlike any tote you’ve ever seen.

We began by throwing away the standard stainless steel tote design playbook. So, for instance, the door is our ‘dynamic door’.

Standard stainless steel solutions have doors that hinge on either side and open from the front. But that necessitates the inclusion of hinges, catches and lock mechanisms which are excellent bacteria traps. This means the user has an additional burden of cleaning in order to keep their totes hygienic.

To simplify matters and help reduce wasted time and effort, we’ve designed away that whole bug-trap area. ALLpaQ has introduced our proprietary ‘Dynamic Door’, which we believe offers unrivalled hygiene and cleanability.

Making this dynamic door transparent (something that remains quite tricky in steel) offers great visibility and control when filling or emptying.

We know that the dynamic door works well, because many of our clients have been successfully employing it since we introduced it to our rigid plastic totes many years ago.

A stainless steel tote is generally a fully-welded component in which the base is permanently fixed to the side panels.

In practice, this is restrictive. It will only allow for one configuration of drain ports, to accommodate the single-use bags to be employed in that tote. If you need to employ different validated bags with tubing in a different arrangement, you will need to purchase a fleet of all-new stainless steel totes, with bases with drains that fit the new bag.

In our 500L Stainless Steel Hybrid Tote, we’ve introduced a revolutionary removable and interchangeable plastic base.

This can be manually lifted out and easily replaced with another custom-made base with a different placement of drain holes.

Simply swap the base, not the entire tote!

This base is made from a unique honeycomb of aluminium that is completely encased in plastic – so it is robust and rigid, but surprisingly lightweight. What makes this a truly hybrid product is that we can customise it to accommodate any number, size or shape of drain ports, to meet the demands of any particular bag.

This results in a single tote with many drain port possibilities.

Also, removing the base makes it much easier to clean the tote and maintain the levels of hygiene you need.

We also have a unique insert for our standard stainless steel dolly that allows it to work with both our plastic Cleanroom totes and our new Hybrid tote.

What does this mean for our customers? Well, rigging for a different bioprocess workflow is simpler and more cost-effective than ever before.

We know that is a very attractive commercial proposition!

We’ve had some excellent feedback on the hybrid tote.

Customers have told us how much they appreciate our Stainless Steel Hybrid tote’s “striking design” which they agree is really innovative and hygienic.

This is great news because Innovation and Hygiene are the key goals we always want to achieve when bringing a disruptive new product to the market.

At ALLpaQ our design team love new challenges and, especially, we love developing new projects. Over the years we have delivered many innovative products to the market through our consultative approach.

So don’t just buy any old tote, invest in an innovative ALLpaQ tote! And, if you have a challenge that your present bioprocess products aren’t solving, get in touch with our team of product architects and let us pioneer something perfect for you.