Company News

Meet ALLpaQ’s Business Development Managers

At ALLpaQ, we understand that the greatest resource of any successful business is its people, and we’re excited to welcome […]

Jul 16th, 2024

Working in the pharmaceuticals and life sciences industries, you may not realise it, but The Internet of Things is here. Believe it or not, they’ve been talking about it for 20 years (the term was coined by one Kevin Ashton of MIT, back in 1999) and, what’s more, it’s estimated that the number of things connected to the net has exceeded the number of people – since 2009!

The point of the Internet of Things – or IoT as it is styled – is to allow devices to talk to each other. The conspicuous front end of this will be your ‘Alexa’ talking to your telly to change channels, or your doorbell talking to your mobile phone when you’re out. But the data these devices capture offers so much opportunity to industry.

The priorities of all pharmaceutical manufacturing companies are, of course, to ensure the quality of the product, to comply with regulations and to create operational efficiencies. IoT can positively impact all of this, across the board; from the manufacture, to the distribution and even to the consumption of the end product.

Given how highly-regulated the manufacture of drugs needs to be, and how critical quality control is within that, IoT’s ability to tirelessly monitor and collate information is invaluable.

Constantly monitoring machines during production can have the effect of reducing waste by saving both resources and time. IoT offers assurances about quality, precision and continuity – it can monitor conditions in labs, factories and warehouses and relate this information to a vast reservoir of data (big data in a very literal sense) to make appropriate decisions on a micro and macro level.

Some people are concerned about the whole notion of machines making decisions. “Do you want Terminators?” the internet meme asks us. But we aren’t asking these computers existentialist questions about the meaning of life, we’re programming them to monitor, report and respond to very specific conditions.

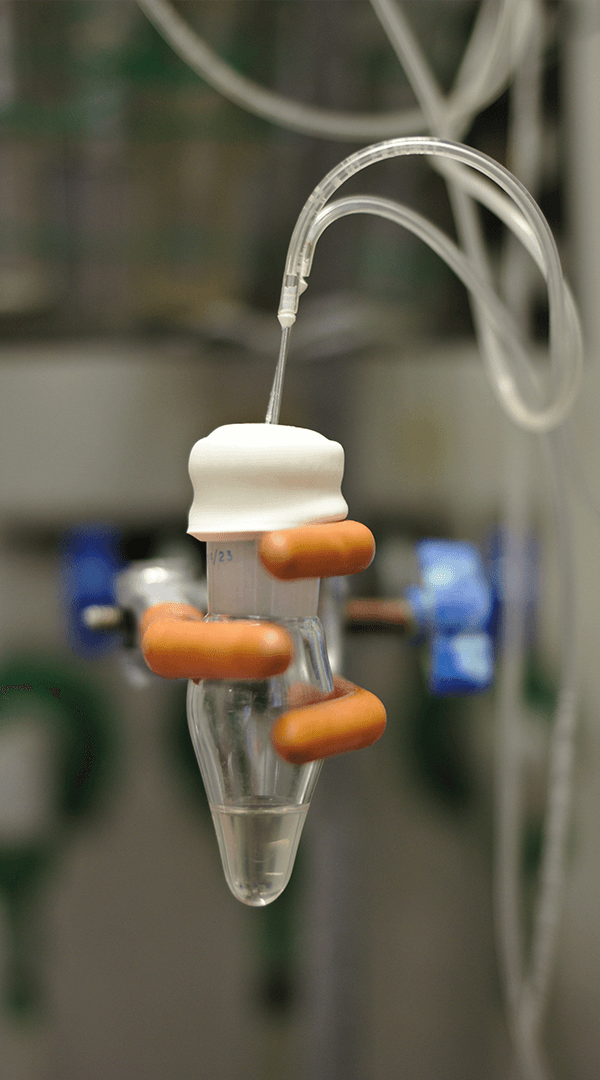

Constant monitoring of pumps, for example, can make adjustments on a second-by-second basis ensuring supply at correct levels and – importantly – should there be any variation or interruption, the IoT can alert the next machine along, to adjust itself accordingly – more quickly and more accurately than any human operator could achieve this. In this way, IoT can ensure that ingredients are quality and quantity controlled throughout.

Similarly, IoT can allow manufacturers to monitor stock levels internally and externally, check the availability of materials in real time, and only order what is needed, exactly when it is needed, and from the most affordable source. This affords far greater flexibility in planning the use of inventory and, inevitably, reduced costs by increasing efficiency.

The raw materials needed to manufacture drugs are generally shipped to the lab or factory by land, sea or air. Once manufactured, the end product will, likewise, need to be transported to other businesses, pharmacies or patients.

During both of these journeys, the products will experience an unpredictable range of climate conditions and altitudes – yet must be maintained at constant and unwavering temperatures, pressures and/or levels of humidity.

IoT can also ensure the provenance of materials, by monitoring the supply chain from the source. Which is clearly an important achievement in an industry targeted by unscrupulous counterfeits and criminal activity.

The proper maintenance of standards, and the evidence of that maintenance, creates a paper-chain of documents, passing from supplier to supplier and from process to process – but paper chains are far from unbreakable.

IoT provides evidence of monitoring at every stage – and can constantly and consistently check for regulatory compliance – then it can report back and store the results, reducing as much as possible the chance of human error and the need for manual input of information, as well as reducing the reliance on filling-in and filing physical hard-copies.

Finally, and most significantly (from the point of view of pharmaceuticals producing some public good), IoT can have a massive impact on the patient’s use of their medicines. IoT devices are regulating patients’ doses, and monitoring effects. This can be especially important in patients who are more dependent on medical intervention, such as older or chronically ill patients, who may not fully understand their conditions, nor the repercussions of failing to take their meds appropriately.

Smart pills, wearable tracking devices, smart patches and even implants are all capable of alerting the patient if they miss a dose, or their condition changes. Family can also be informed and, if and when necessary, medical professionals can be automatically contacted.

Large industries – especially heavily-regulated large industries – can be slow to adopt new technology and new strategies, if only because of the questions over legislation and the sheer cost of new equipment. But, once the benefits are widely understood, IoT’s adoption in the pharmaceuticals and life-sciences sector becomes inevitable.

In that way, we at ALLpaQ like to think we’re ahead of the curve.

Why not give us a call on +44 (0) 1472 800 373, email us enquiries@allpaq.com or simply fill in the form below.