posted by Phill Allen

September, 16th, 2014

Company News Pharmaceutical Industry News

When we talk about upstream bioprocessing, Captain Pugwash sailing merrily on his pirate ship might come to mind. In reality, upstream bioprocessing describes a slightly more technical process – only ever so slight, mind you.

When we talk about upstream bioprocessing, Captain Pugwash sailing merrily on his pirate ship might come to mind. In reality, upstream bioprocessing describes a slightly more technical process – only ever so slight, mind you.

A bioprocess refers to a process which involves the use of complete living cells or their components – think of bacteria, enzymes, chloroplasts – to develop desired products.

Now, therapeutic cell manufacturing processes can be divided into two clear camps: 1) upstream processes 2) downstream processes.

Upstream bioprocessing

The upstream part of a bioprocess refers to the first phase in which microbes/cells are grown in bioreactors.

Fermentation falls into two parts: upstream and downstream. Following on from product development, purification of the product is need to ensure the desired quality. At this stage, they are harvested and pushed down to the downstream section of the bioprocess.

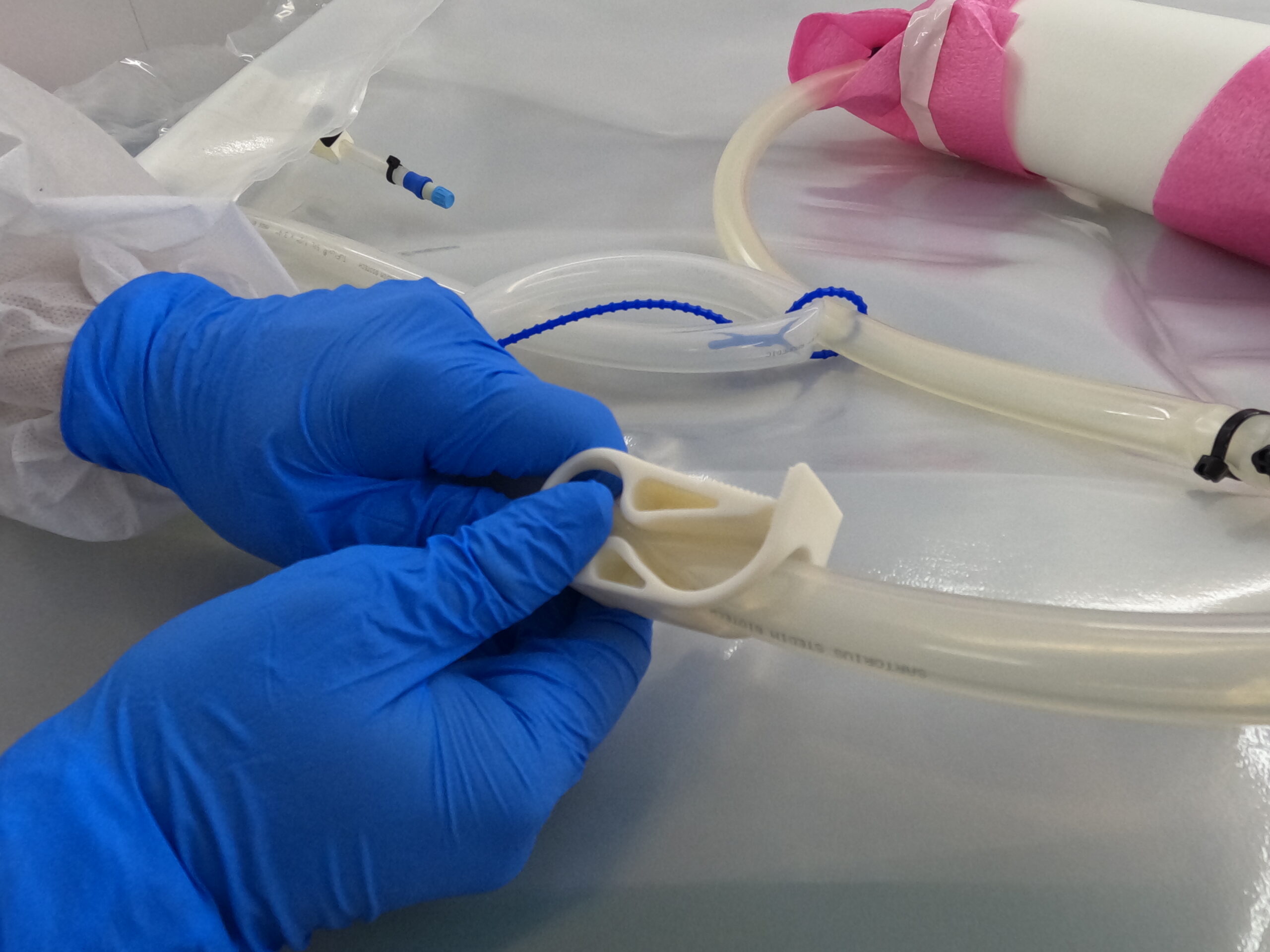

Bioprocess containment

So what do we do with all this valuable media? How do we protect, store and transport it along the supply chain? This is where bioprocess containment comes in. Managers in the biopharmaceutical industry face a choice between plastic or steel bioprocess containers.

The material of the container is of key consideration to industry as they both offer different operational outcomes. Plastic bioprocess containers, for instance, enhance the supply chain along which the media travels.

From manual handling, to warehousing, to shipment, the lightweight, stackable, foldable design of ALLpaQ all-plastic bioprocess containers delivers operational and cost benefits at all rungs of the supply chain.

Find out more about bioprocess containment

Related reading:

TAGS:

Downstream Bioprocessing, upstream bioprocessing,

SHARE:

Author

Phill Allen

Managing Director

Phill is an innovative thinker particularly in fluid management. His expertise lies in ensuring the seamless flow of pharmaceutical liquid logistics, whether it's optimising current processes or pioneering new approaches.