posted by Phill Allen

September, 22nd, 2021

Company News Pharmaceutical Industry News

To go plastic biocontainers or not to go plastic biocontainers? That is the question when it comes to fluid management.

Deciding between plastic or steel biocontainers for processing, storing and shipping your valuable media is indeed a bit of a head scratcher.

Besides offering your valuable media Fort Knox levels of protection, bioprocess containment also plays a key role in:

- Manufacturing and storage space optimisation

- Supply chain efficacy

- Logistics planning and costs

- Cleaning and validation costs

- Stakeholder satisfaction

So, when it comes to choosing your tipple, it’s important to get it right.

Plastic versus steel bioprocess containers

As a manager in the biopharmaceutical industry, chances are you’ve previously opted for the steel solution. This is understandable. Steel, after all, boasts a history of stainless prestige.

“It lasts forever, doesn’t rust and is unbreakable,” so traditionalist say. Even Superman was branded the Man of Steel and that guy could fly.

Yet, sentiment has failed to stop progress. The plastic revolution is upon us and more biopharmaceutical companies are making the change to plastic.

Why is this the case? Because plastic biocontainers enhance the sustainability and profitability of businesses – something even the Man of Steel couldn’t achieve.

Let’s take a look:

6 reasons why plastic is fantastic

1. Collapsible and stackable

Fabricating in plastic means your containers can be easily collapsed and stacked, allowing you to maximize your warehousing floorspace. This also presents space and cost utilisation benefits when in shipment.

2. Manual handling

Unlike the weighty steel equivalent, our bioprocess containers are lightweight and collapsible. This makes manual handling so much easier, allowing you to align with the rigours of health and safety requirements.

3. Foldable

ALLpaQ containers can be folded to save space in return shipment. Plastic is also lighter than steel, generating a reduction in shipping charges.

4. Reusable and recyclable

ALLpaQ bioprocess containers can be used time and time again and, in the event of damage, individual panels can be removed and replaced. This adds to the lifespan of your fleet, enhancing sustainability and your bottom line.

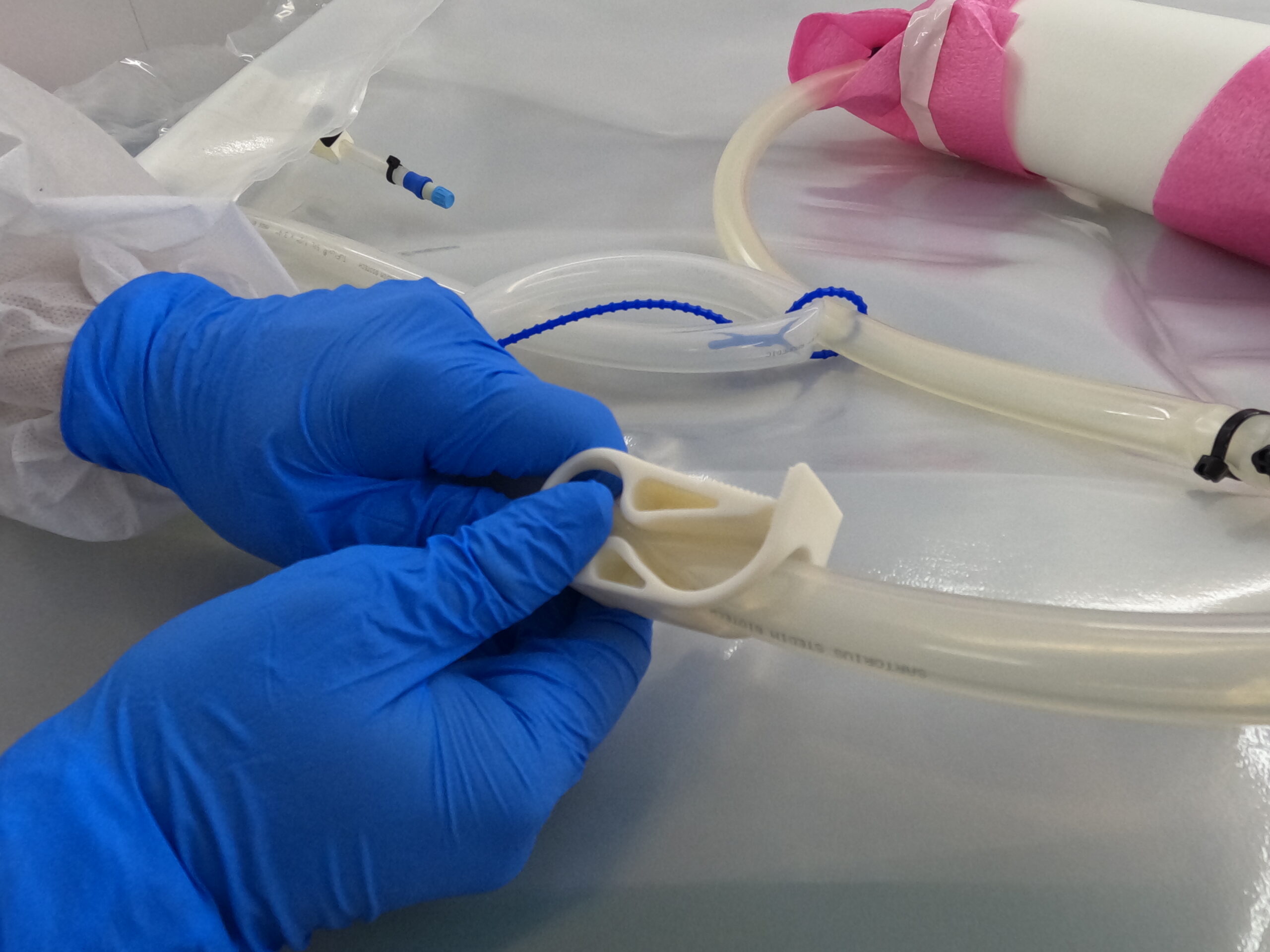

5. Hygiene

Plastic is easier to clean than steel. ALLpaQ products offer better spillage control and can be easily and quickly jet washed. If needed, individual panels can also be removed for cleaning.

6. Cost effective

Plastic bioprocess containers are more economical, user friendly and easy to maintain – all healthy for your company’s commercial and operational goals.

What to do next?

Need help with fluid management? Our team of bioprocess specialists are standing-by to talk. Fill in the form below and we’ll be in touch.

TAGS:

biocontainers, Biopharmaceutical, Plastic Bioprocess Containers, steel totes,

SHARE:

Author

Phill Allen

Managing Director

Phill is an innovative thinker particularly in fluid management. His expertise lies in ensuring the seamless flow of pharmaceutical liquid logistics, whether it's optimising current processes or pioneering new approaches.