Pharmaceutical Industry News

Downstream vs upstream processing

Upstream and downstream processing work in tandem to produce desirable products, such as beneficial pharmaceuticals like medicines or biochemicals. But […]

Oct 21st, 2025

At ALLpaQ, we like to think we have earned our place as the world’s premier producer of plastic bioprocess containers by keeping an eye on the sector and catering for its needs. To an extent, this relies on us knowing what businesses will need before they know it themselves.

We can then plan, design, fabricate, test, validate and manufacture a product to ensure that it’s ready for when the phone rings with the message “I don’t suppose you have…?”

In order to have a holistic view of our sector, we need to keep an eye on business predictions and this one was particularly welcome. Research was recently published that predicts a massive growth in the bioprocess container marketplace in the next few years.

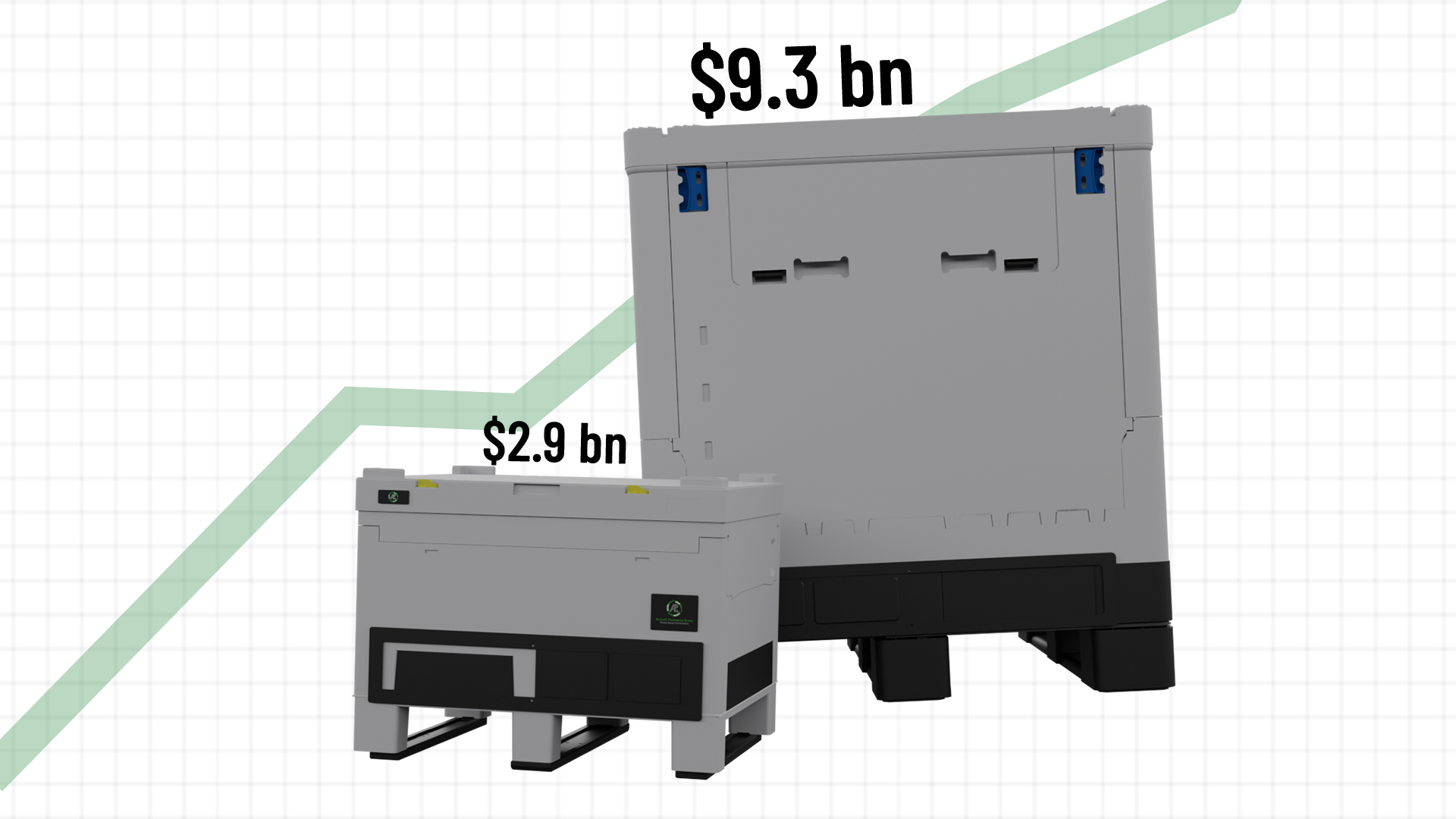

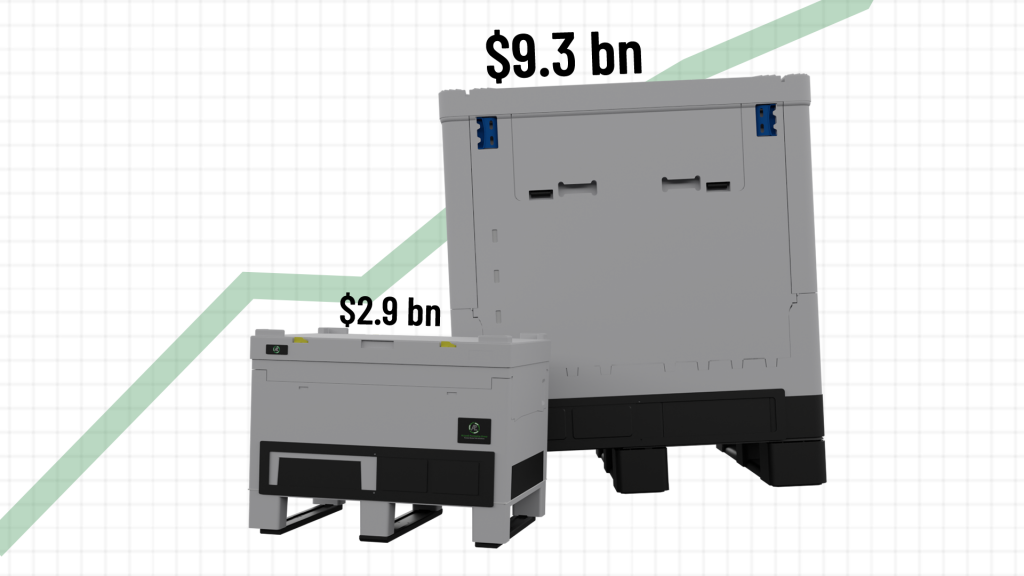

Transparency Market Research has released a report that states that the global bioprocess container market in 2022 was valued at US$2.9 bn (approx. GB£2.34 bn). This is projected to grow by 11% per year for the foreseeable future – leading to a potential marketplace of US$ 9.3 bn (approx. GB£7.5 bn) by 2033.

Alternative market research indicates that a similar growth will be achieved much earlier, by 2026. Either way, we are riding a wave of increased need – principally in high-quality single-use 2D and 3D bioprocess containers. This offers agile companies like ours a plethora of opportunities.

There are various factors at play here. Certainly, there has been a global increase in demand for biological materials such as cell cultures, media, buffers, vaccines and biosimilars. But, why?

Additional research by Mordor Intelligence indicates some of the key factors driving the growth of the bioprocess container market are:

The use of plastic bioprocess containers is also expected to experience a significant growth rate over the next few years. We have led the field in adopting plastic as the solution to many of the workflow challenges that the life sciences sector faces.

It is now widely recognised that plastic bioprocess containers offer many benefits, such as:

As you can see, the outlook for a manufacturer of bioprocess containers such as ourselves is positive and promising. But, as with any business, as well as a wide range of opportunities, there are also challenges we face, for example:

We, at ALLpaQ, can address all of those concerns because no other manufacturer in our field has our track record.

ALLpaQ has been designing and manufacturing made-to-measure, cutting-edge bioprocess solutions, in consultation with clients, for almost 20 years.

We welcome stringent regulations because, at ALLpaQ, we care about the quality of our products and of our clients’ products. We also do things the right way for our team, customers, community and environment. This is acknowledged through a variety of hard-earned accreditations and rewards from leading bodies.

Our work is rigorously evaluated and overseen by the world’s most reputable standards bodies. Check out the full list of accreditation bodies who ensure our products are of the highest quality and produced with an eye on responsible business and sustainability.

Our technology and manufacturing techniques are the finest known to man and many of those techniques are closely-guarded proprietary secrets.

Agile customisation is the name of the ALLpaQ game – we love a challenge from a customer. This leads to innovation and, therefore, a brighter, more productive, more lucrative future both for us and for our clients.

If you’d like to know how we intend to play a major role in the growing marketplace – just get in touch by filling in the form below.

If you’ve been let down by an inferior supplier, or you feel you have a business challenge that off-the-shelf products can’t accommodate – tell us all about it. Our design and fabrication team love a challenge!

At ALLpaQ, the answer is always “yes!”

That’s how we got where we are, and that’s why we’re perfectly positioned to lead the field in the future of the bioprocess container market!