Space: the final frontier. These are the voyages of your biopharmaceutical business and its mission to seek out new ways of optimising space when storing media.

Space: the final frontier. These are the voyages of your biopharmaceutical business and its mission to seek out new ways of optimising space when storing media.

In today’s frosty financial atmosphere, industry leaders are indeed boldly going where no man has gone before in efforts to optimise the floor space available to them in warehousing.

This is particularly the case when it comes to bioprocess containment. After all, for many in the biopharmaceutical industry, storing media inside steel bioprocess containers is second nature.

When warehousing these hefty units though, space is quickly vacuumed into a black hole – the gravitational force of burgeoning operational costs weighing heavy on the shoulders of business.

Many companies subsequently look to redesign their warehouses or even minimise lease and ownership expense by combining facilities. Both of these options can be time-consuming and, according to some members of industry, lead to sub-optimal results.

What if we were to tell you, then, that there is a far easier and cost-effective way to optimise your warehousing space? Well, the secret of this universe is all-plastic bioprocess containers.

Plastic bioprocess containment: light years ahead

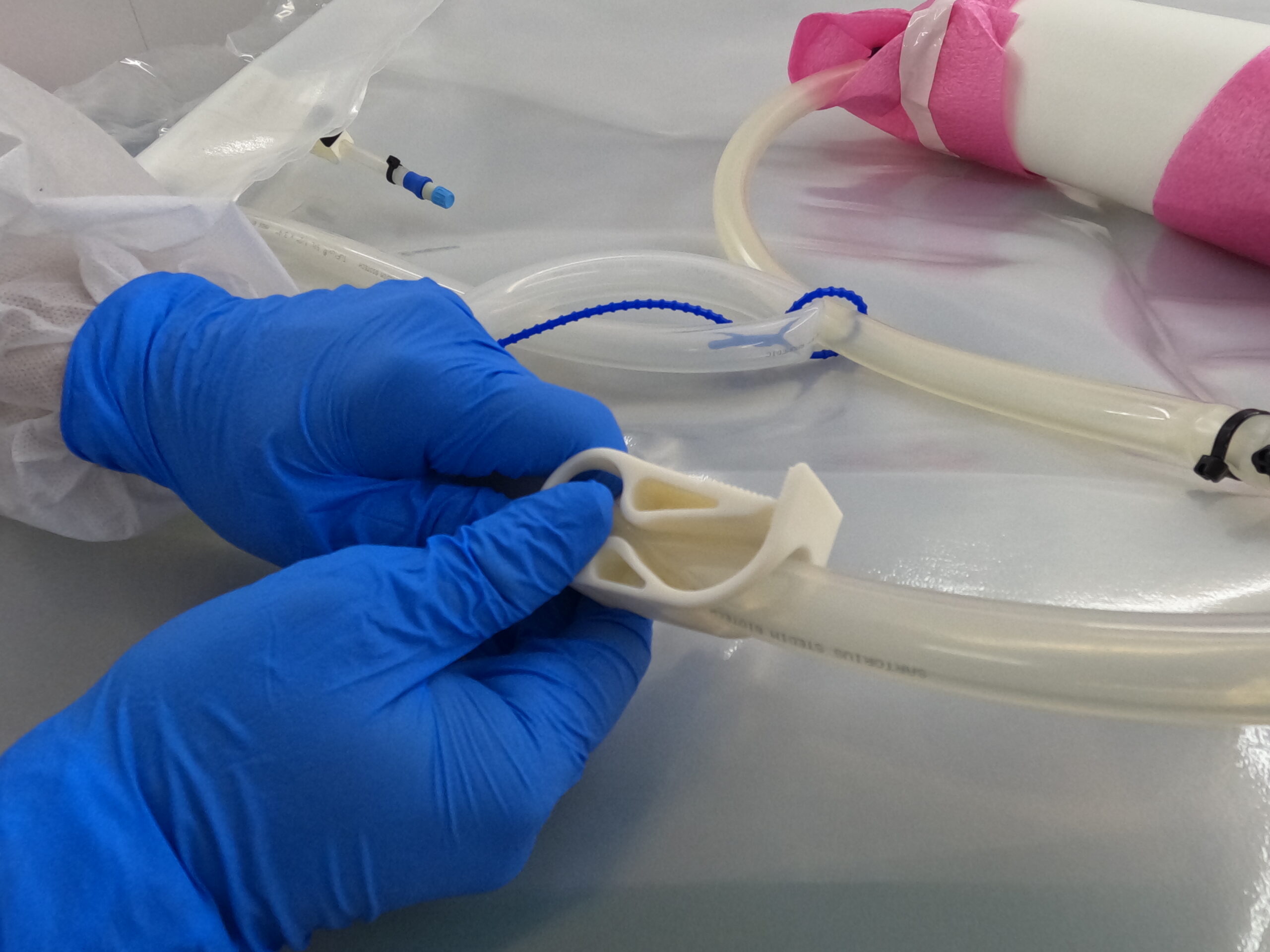

Increased space optimisation is a key industry requirement and, as such, is engineered into the design of ALLpaQ bioprocess containers.

How, you ask? Well plastic bioprocess containers – unlike the steel equivalents you may be used to – offer business an array of operational and commercial benefits.

Steel, of course, is more inflexible than a frozen yoghurt. Plastic, on the other hand, is more flexible than a limbo dancer. This, in turn, means we can fabricate bioprocess containers around the operational needs of your business.

Collapsible and stackable

Fabricating in plastic means our bioprocess containers can be easily collapsed and stacked, allowing you to maximise every inch of your warehousing space. Better utilising your existing space can generate huge cost savings.

Likewise, the units can be folded to save space in return shipment – everyone’s a winner baby and that’s the truth.

What to do next?

Plastic bioprocess containers mark one small step for a man and one giant leap for the biopharmaceutical industry.

Get in touch to find out more.

TAGS:

Biopharmaceutical, bioprocess containment, Space optimisation,

SHARE:

Author

Phill Allen

Managing Director

Phill is an innovative thinker particularly in fluid management. His expertise lies in ensuring the seamless flow of pharmaceutical liquid logistics, whether it's optimising current processes or pioneering new approaches.