posted by Phill Allen

November, 10th, 2024

Company News Pharmaceutical Industry News

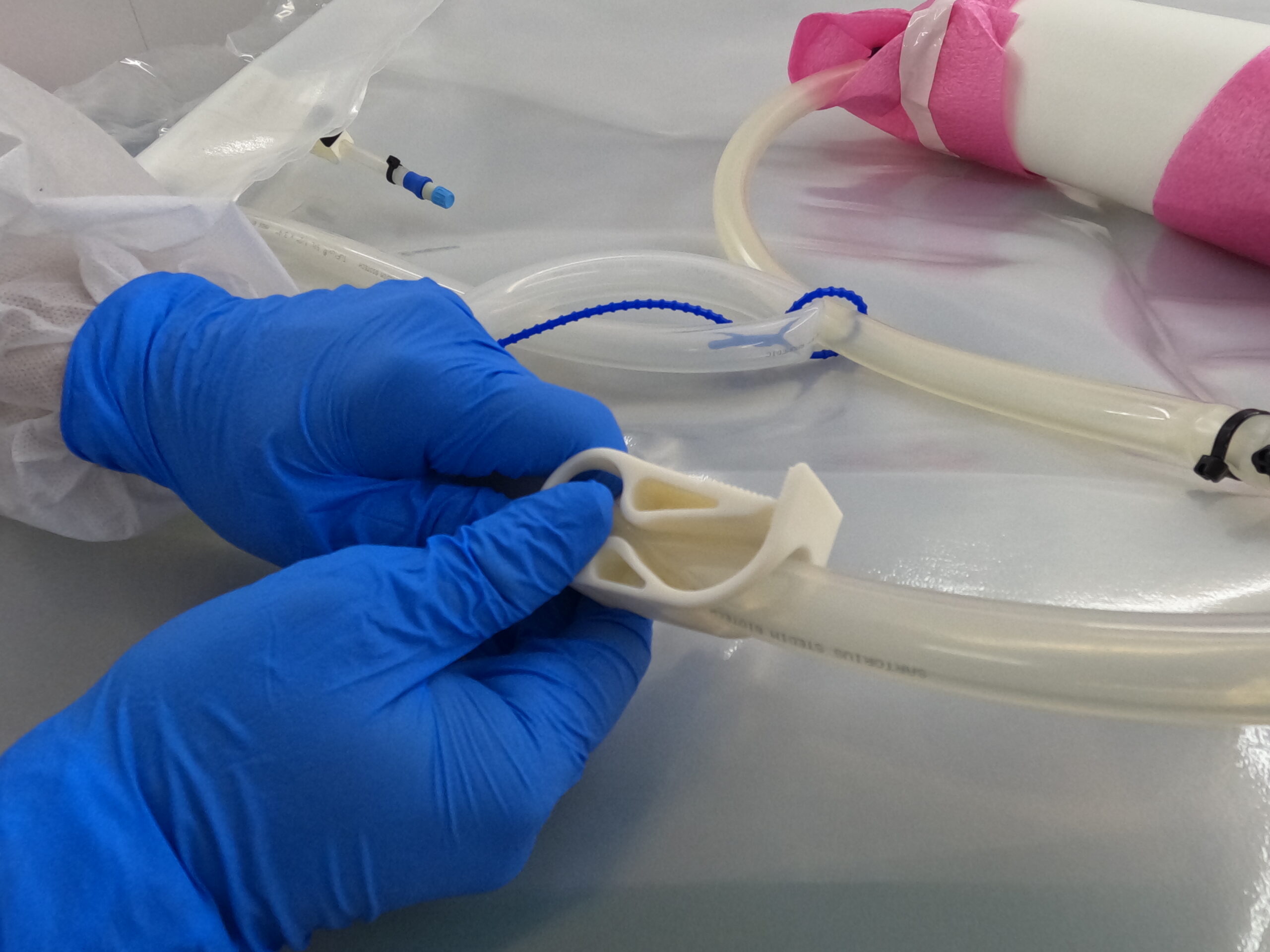

Bioprocess containment remains a part of daily fluid handling life for pharmaceutical and life science companies. This is a reality.

As such, we all have a duty to package responsibly. In this ever-shrinking world of ours, actions that benefit the wider community are actions worth taking. At least, that’s the way we see it at ALLpaQ.

It follows then that our bioprocess containers are uniquely fabricated to streamline supply chains, minimise waste and reduce carbon emissions. How, you ask?

Environmentally savvy packaging designs

Reuse, return, recycle: this brand mantra is built into every inch of our bioprocess containers. As such, ALLpaQ designs break the rigid mould of traditional steel containers.

Reuse: ALLpaQ bioprocess containers can be used time and time again. And, in the event of damage, individual panels can be removed and replaced.

This adds to the lifespan of your bioprocess containment fleet, enhancing sustainability and your bottom line.

Return and recycle: We’re corporate. We’re social. We’re responsible. At ALLpaQ, we are committed to a responsible future through recycling plastic bioprocess containers. This means we’ll always accept bioprocess containers from the customer to go to recycling.

We only ever manufacture containers from virgin materials as, like all plastic, they can be recycled. This is important. After all, the benefits of recycling include:

- Less plastic in landfill

- Reduction in oil consumption in plastic production

- Reduction in energy consumption

- Reduction in CO2 carbon emissions

Got a question?

Fire away. Your dedicated fluid handling consultant will get right back to you.

Make contact

TAGS:

Biopharmaceutical, Bioprocess Containers, enviroment, Pharmaceutical,

SHARE:

Author

Phill Allen

Managing Director

Phill is an innovative thinker particularly in fluid management. His expertise lies in ensuring the seamless flow of pharmaceutical liquid logistics, whether it's optimising current processes or pioneering new approaches.