posted by Phill Allen

August, 18th, 2014

Company News Pharmaceutical Industry News

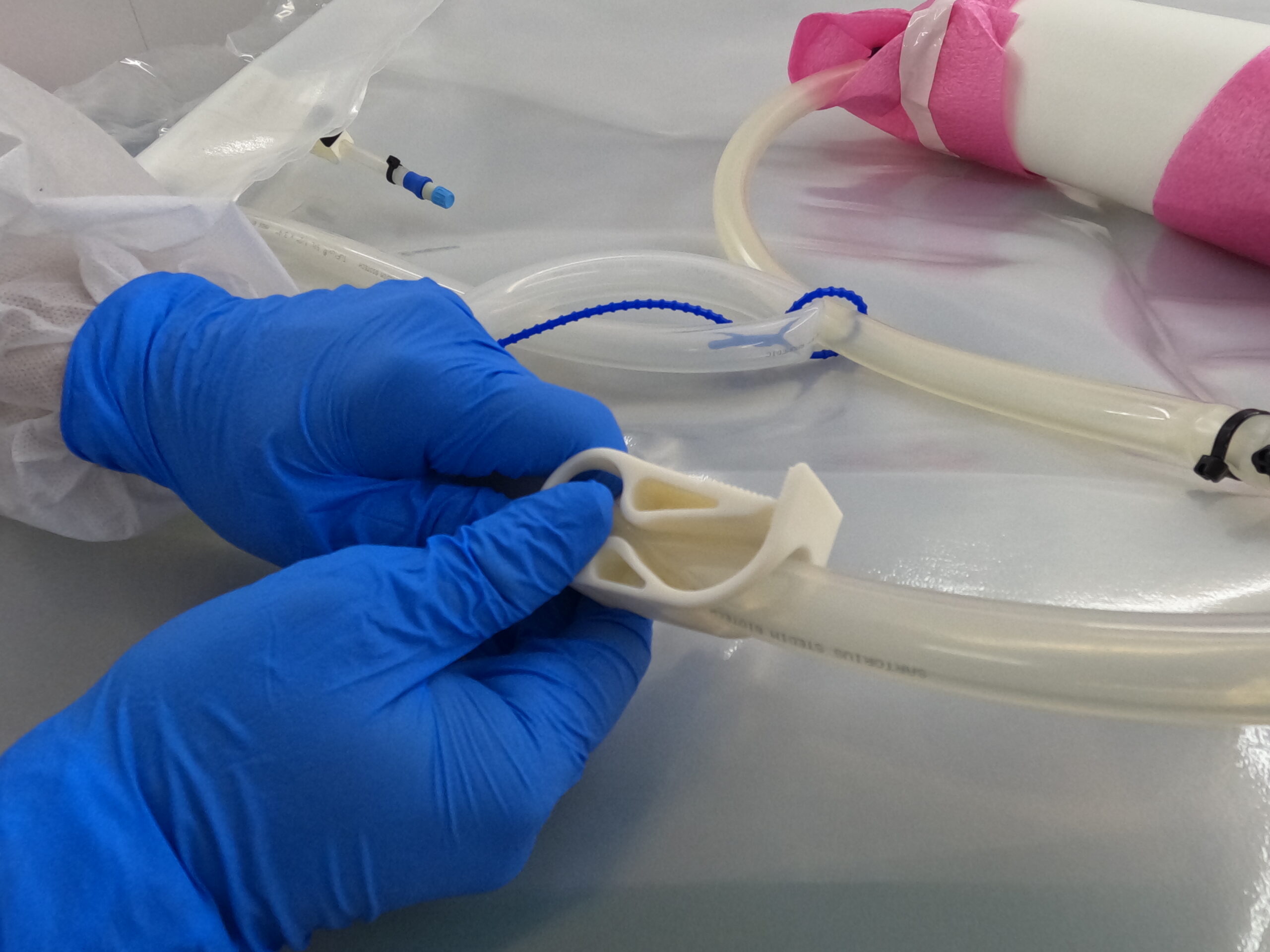

Is plastic bioprocess containment the right pill for the pharmaceutical industry? When it comes to secondary packaging, you face a choice between plastic and steel.

Which way to go? Back in 1999’s The Matrix, Neo faced a similar choice when Morpheus offered the chosen ‘One’ a choice between popping the blue or the red pill.

“You take the blue pill – the story ends,” says Morpheus. “You take the red pill – you stay in Wonderland and I show you how deep the rabbit hole goes.”

Plastic bioprocess containers are akin to the red pill for the pharmaceutical industry. For those who are yet to move to plastic containment, the dream of plastic remains just that: a dream.

But for those who already embrace plastic containment, the dream world is now the real world, a place where cost-savings and supply chain rationalisation have become the norm.

Those who take the red pill enjoy:

1. Collapsible and stackable

Fabricating in plastic means ALLpaQ bioprocess containers can be easily collapsed and stacked, allowing pharmaceutical companies to maximise warehouse floor space. This also presents space and cost benefits when in shipment.

2. Reusable and recyclable

ALLpaq bioprocess containers can be used time and time again and, unlike stainless steel containers, in the event of damage individual panels can be removed and replaced. This in turn adds to the lifespan of your fleet, enhancing sustainability and your profit margins.

3. Hygiene

Plastic is easier to clean than steel and can be quickly jet washed. If needed, individual panels can also be removed for cleaning.

What to do next?

Follow us down the rabbit hole and view the ALLpaQ range of all-plastic bioprocess containers.

TAGS:

Biopharmaceutical, Pharmaceutical, plastic bioprocess containment,

SHARE:

Author

Phill Allen

Managing Director

Phill is an innovative thinker particularly in fluid management. His expertise lies in ensuring the seamless flow of pharmaceutical liquid logistics, whether it's optimising current processes or pioneering new approaches.