posted by Phill Allen

November, 17th, 2014

Company News Pharmaceutical Industry News

ALLpaQ AIR took flight earlier this year. The latest addition to our fleet of bioprocess containers evolves the way you ship biopharmaceutical media held in environmental control.

AIR’s strategic design ensures no spare space is wasted inside an Envirotainer RAP e2 container. This means that when your media is cruising at 35,000 feet, you’ll also be flying high as:

- The storage space available to you has been fully optimised

- You can transport more biopharmaceutical media per flight

- Your organisation will see a sizeable reduction in shipping costs as well as carbon emissions

Prior to lift off, the developed prototype successfully underwent independent structural and transportation tests. These were conducted by Smithers Pira in the United Kingdom in accordance with ASTM D4169-09, Distribution Cycle 12 for air and motor freight, Assurance Level II.

AIR has been included in the standard portfolio of bioprocess containers available exclusively through ALLpaQ and its appointed distributors.

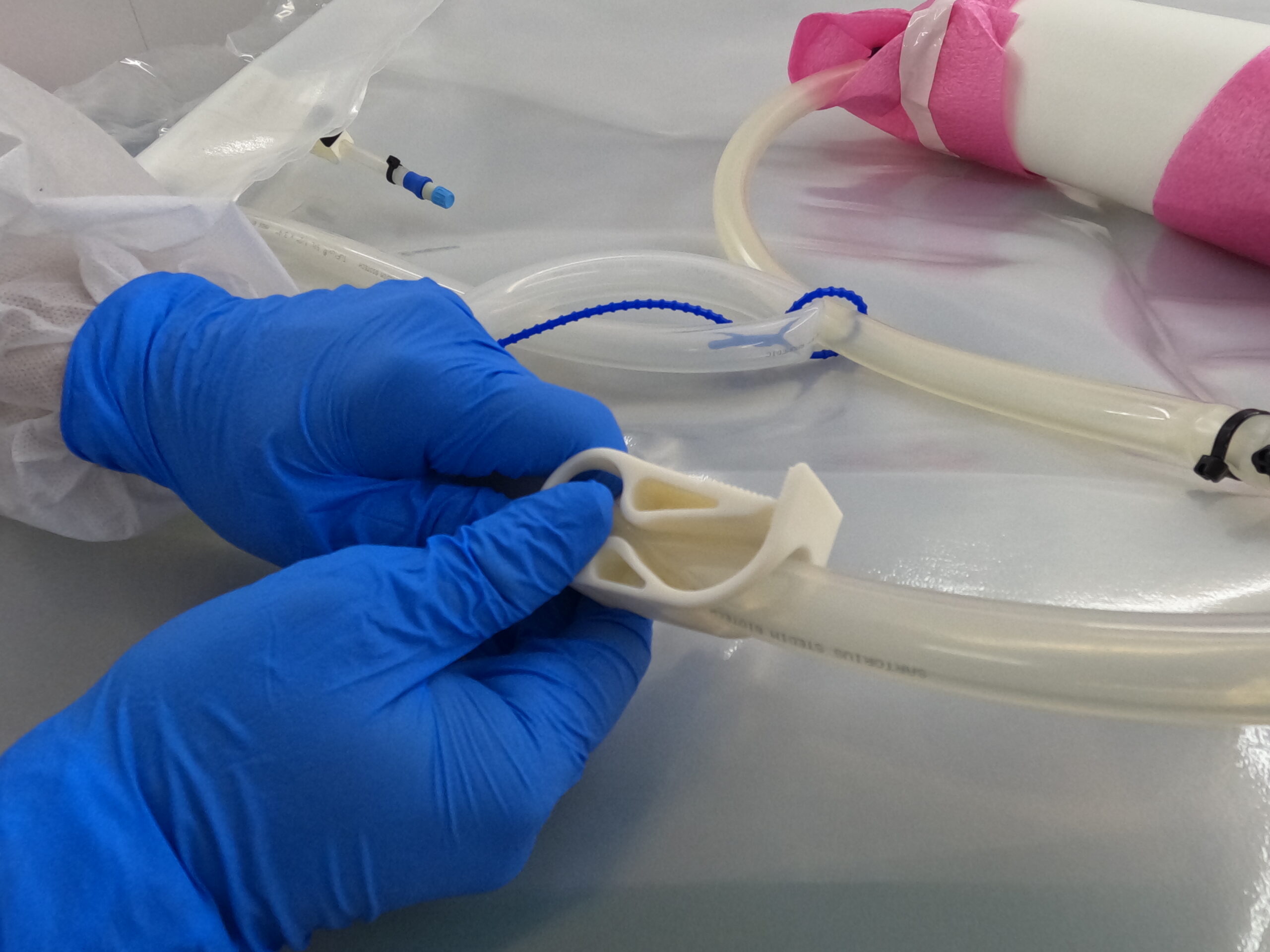

We caught the unfolding validation action on camera.

Watch bioprocess containment testing video

Got a question?

Want to find out more about how ALLpaQ AIR and our range of bioprocess containers infuse your fluid handling supply chain with fiscal and environmental sustainability? Okay, no problems. Make contact and one of our fluid handling attendants will get right back to you.

Make contact

TAGS:

ALLpaQ AIR, Bioprocess Containers, Envirotainer,

SHARE:

Author

Phill Allen

Managing Director

Phill is an innovative thinker particularly in fluid management. His expertise lies in ensuring the seamless flow of pharmaceutical liquid logistics, whether it's optimising current processes or pioneering new approaches.