posted by Phill Allen

February, 26th, 2018

Company News Pharmaceutical Industry News

Remember the New England Compounding Center scandal? If you need your memory jogging, the NECC caused an outbreak of spinal meningitis in over 800 patients across the US, resulting in the death of 76 people.

An investigation of the NECC found that the company had been creating pharmaceuticals for broad use rather than individual prescriptions for the unique needs of each patient. Poor quality control and management of the drugs meant that the products were mislabeled and contaminated.

To assess where hospital-based pharma production stands today, a white paper, ‘Roundtable on Patient Safety’, conducted by stakeholders concluded that the current case of production is unsatisfactory.

Stakeholders found that there were too many compounding errors, most of which were due to human error. Challenges still exist in regulating and enforcing compounding safety guidelines, which leads to a strong need for increased training and support for the curriculum of sterile compounding practices.

The Roundtable’s assessment is supported by FDA data, which on their website lists 63,503B fatalities and another page lists many Form 381 warning letters to pharmacies.

Could technology be the answer?

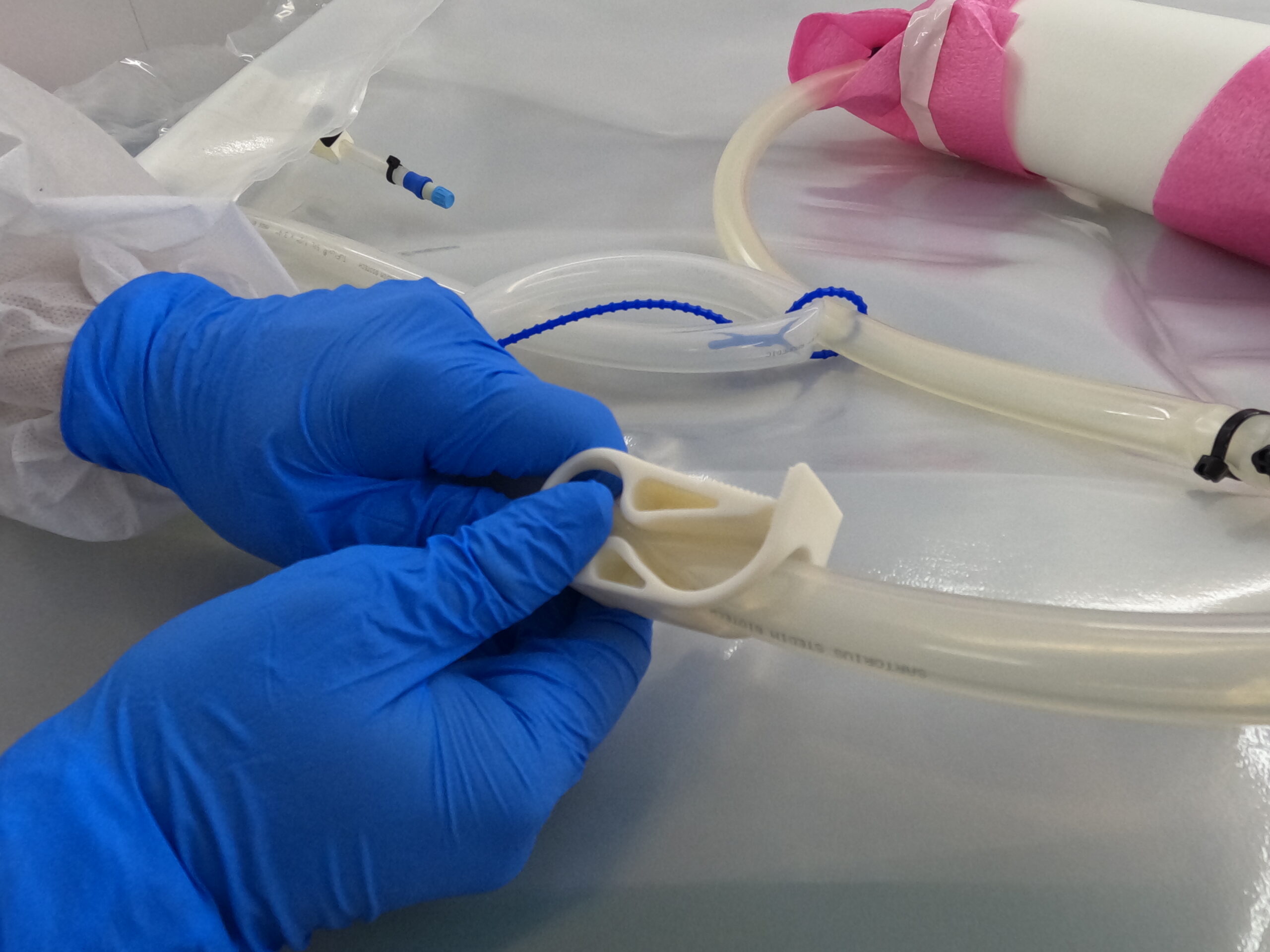

The idea of technology is favoured by the Roundtable as they believe that it could reduce hazards in IV admixture, gravimetric testing and barcoding.

Only 20% of hospitals employ this type of technology, but it’s unclear whether this is based on all US hospitals as some seek compounding to providers such as Pharmedium.

Arxium, a leader in automated compounding systems, claims that employing automated IV equipment can prevent over 3,200 adverse drug effects for the average hospital.

TAGS:

automated compounding, Bioprocessing, NECC, pharma, pharmaceutical industry, pharmacy technology,

SHARE:

Author

Phill Allen

Managing Director

Phill is an innovative thinker particularly in fluid management. His expertise lies in ensuring the seamless flow of pharmaceutical liquid logistics, whether it's optimising current processes or pioneering new approaches.