Accessories Containers Environmental

What is bioprocessing equipment?

Bioprocessing is an essential process that’s central to the formulation of medicines and vaccines that people depend on every day, […]

Jul 14th, 2025

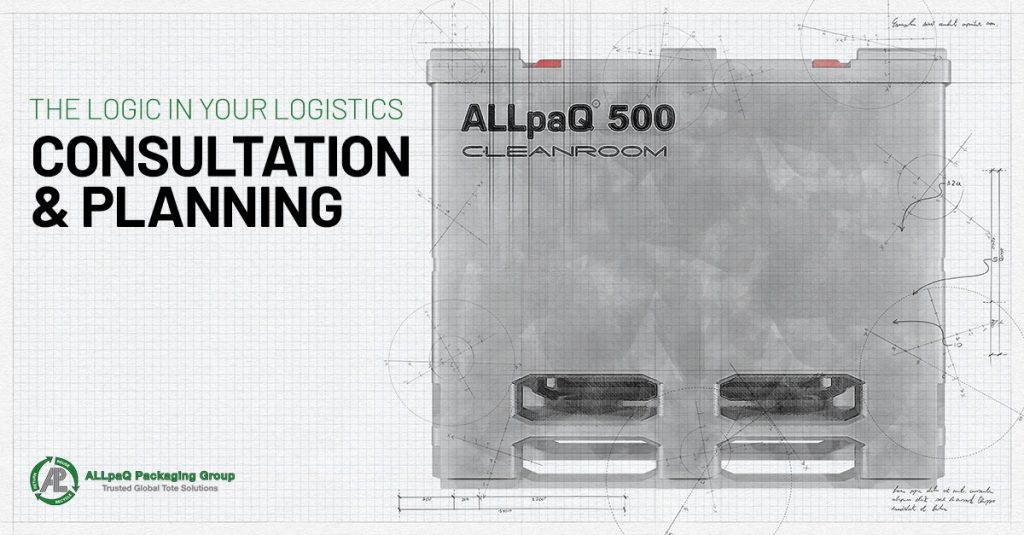

From discovery and development to clinical testing and manufacturing, your bioprocess is unique, which means you need – and deserve – unique bioprocess containers and fluid management accessories.

For ‘unique’, read ‘ALLpaQ’.

With ALLpaQ, we believe you’ll get a unique customer experience – because we offer, as standard, the understanding, problem-solving expertise and precise customisation you need to optimise your fluid management strategy at every stage, from initial conception to delivery at commercial scale.

Our process and fabrication team will design then build your custom units, all under our own roof and all under ISO 9001 certification. That way we can ensure quality control and guarantee that you will get the specifications you need.

Be reassured – we create unique customised solutions for your solutions, and you can check out our typical custom bioprocess container workflow here.

Here at ALLpaQ, we’ve never met a customisability challenge we didn’t love and we pride ourselves on giving our clients a complete in-house service. Products are designed by our own technical/CAD team, fabricated by our own plastic welding specialists and supplied to requirements by our experienced sales team.

Our fluid management strategy A-Team can configure our bioprocess containers and accessories to adapt, improve and overcome your workflow.

For example, ALLpaQ’s wide range of shipping, warehousing and cleanroom intermediate bulk liquid totes can be updated to accommodate every bag format and brand on the market, from 2D and 3D bioprocessing bags to matching bag port positions for filling, draining and processing. Whatever primary packaging you use, we can customise a bespoke secondary packaging solution that fits like a proverbial glove.

A typical design workflow has five key stages. We’ll consult with you throughout the process, to ensure you know what you’re getting and that it is exactly what you want and need.

We get it right the first time, almost every time. But, given the importance of your process, if tweaks are required we will prioritise them and implement them at pace.

That’s our process for every ALLpaQ product, designed, fabricated and delivered by us – to our worldwide network of pharmaceutical clients.

We’d love to hear from you about your next project or ongoing processes, so we can discuss exactly what the ALLpaQ A-Team can do to help you adapt, improve and overcome. Our fluid management specialists are standing by to talk. Let’s change your life (sciences) today.