posted by Niamh Allen

January, 14th, 2025

Containers Product News

The exciting applications of biotechnology aren’t limited to one singular sector – in fact, a plethora of industries benefit from bioprocessing technology.

Within this article, we explain the bioproduction processes harnessed across several essential industries and the high value products mass-produced from them.

You won’t want to miss this!

Defining bioprocessing

Bioprocessing is the creation of beneficial materials from living organisms – the organic source must be alive, and may include living cells, bacteria, enzymes, chloroplasts or other biological components.

Bioprocessing methods require a biocatalyst to grow, develop and harvest the organic materials produced by the living organism. Bioprocessing applications are vast, and are employed across various sectors for the industrial manufacturing of a desired product.

Bioprocessing in the pharmaceutical industry

The ultimate goal of bioprocessing in the pharmaceutical sector is new drug development to combat diseases, infections and illnesses. Vaccines, antibiotics and insulin are just a few examples of the desired products developed as a result of the bioproduction process.

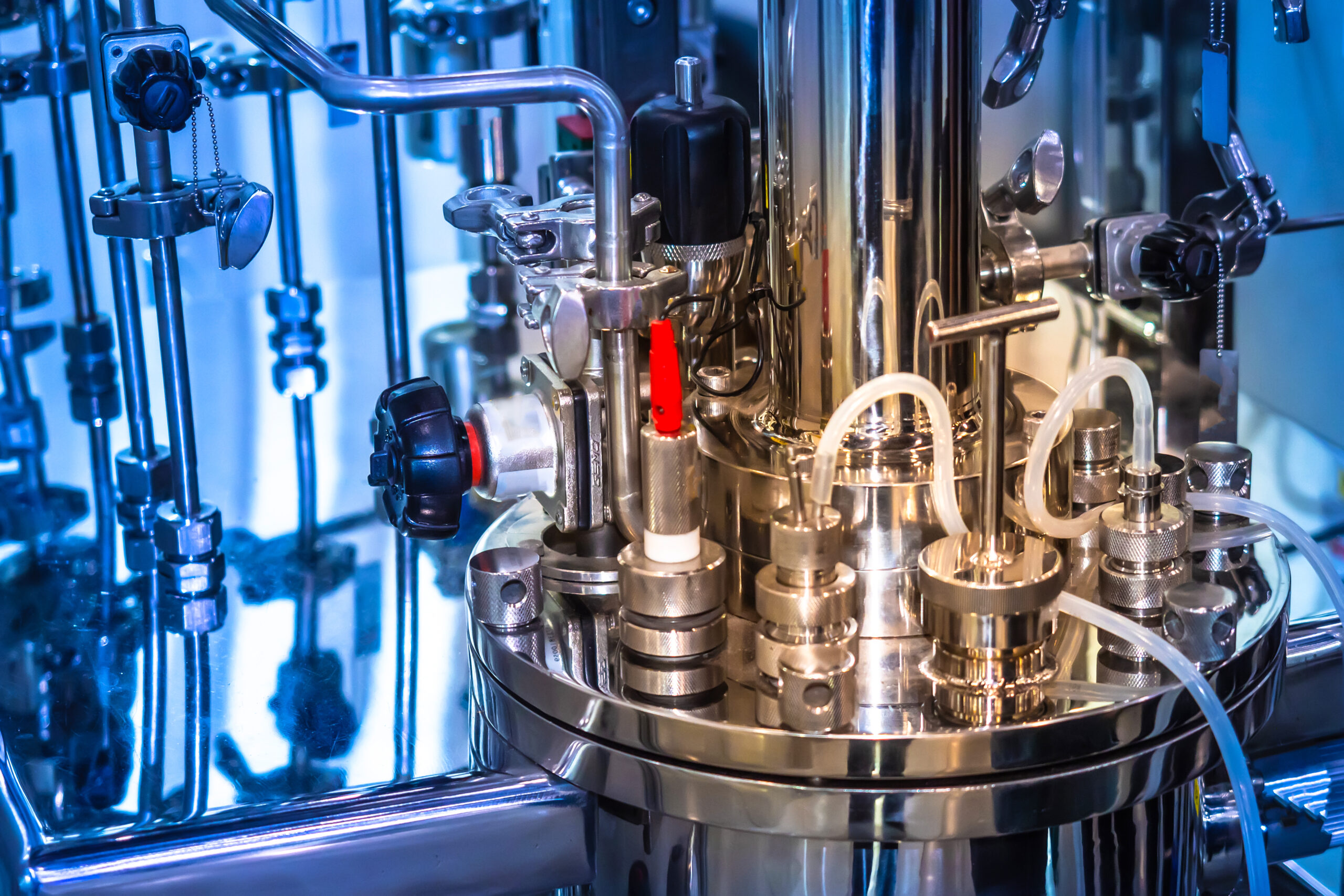

Biopharmaceutical manufacturing employs fairly complex bioprocessing techniques consisting of upstream and downstream processing.

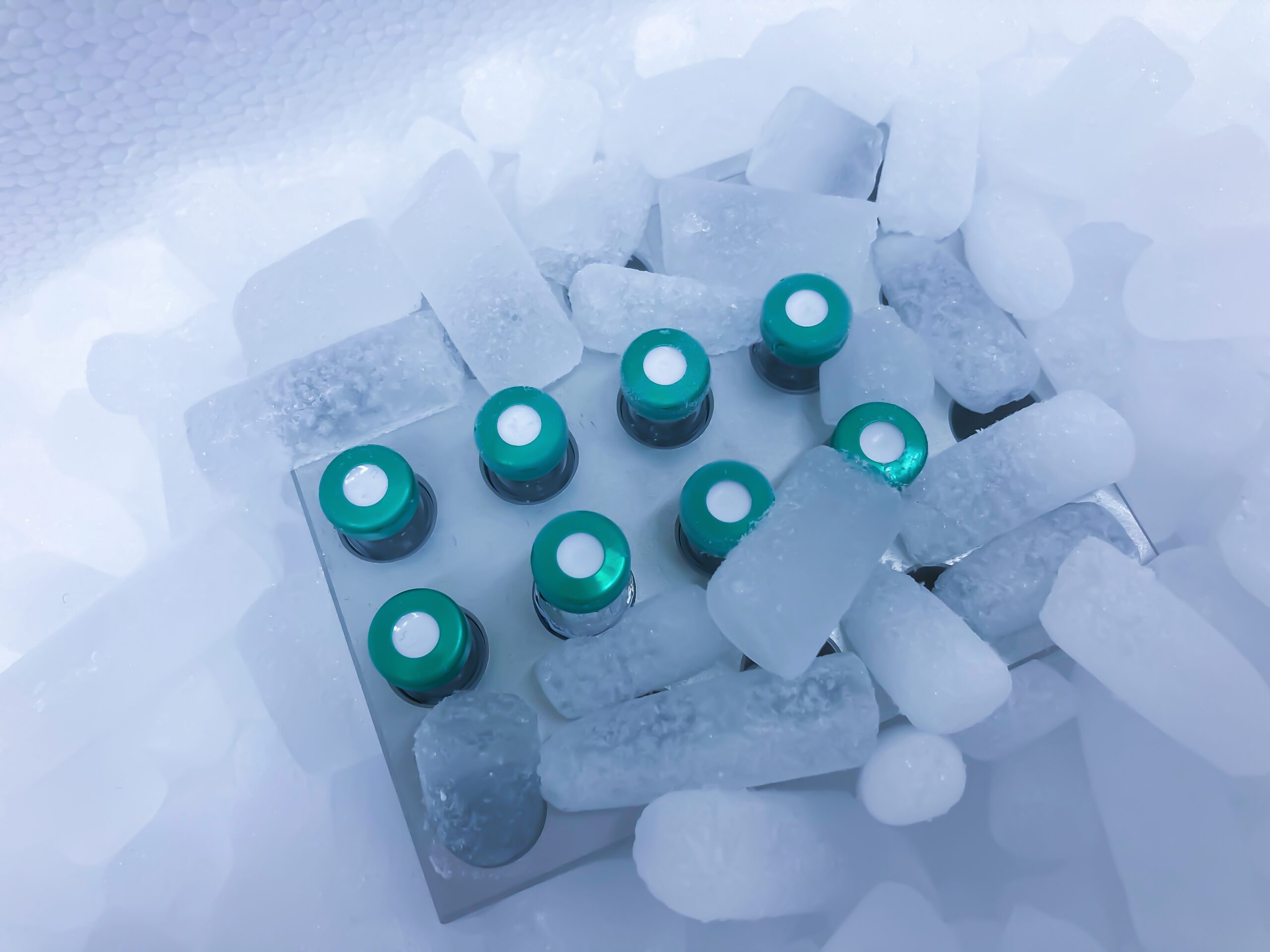

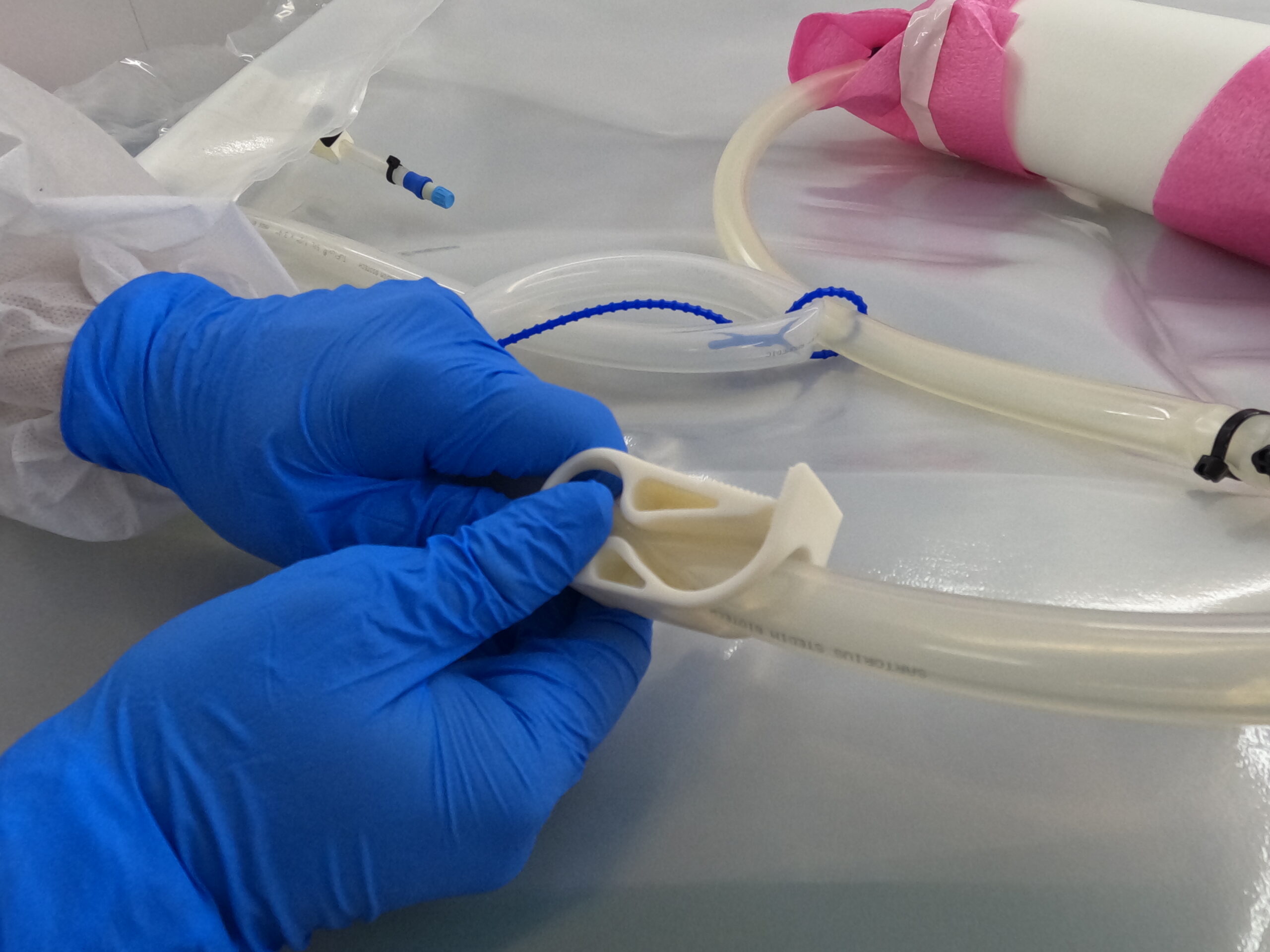

Both phases require effective fluid-handling systems such as bioprocess containers to store, manage and transport the numerous liquids utilised throughout the drug development process, such as bioreactor feeds.

Upstream processing

Upstream processing refers to the initial stages of drug development and aims to maximise cell growth and product yield.

During this phase, the biological material is selected. Organisms, such as bacteria or mammalian cells, are chosen based on the intended product, such as therapeutic proteins like insulin.aximise the yield and quality of new medicines.

This is followed by culture media preparation, inoculation, cell culture and fermentation to prepare the biomass for downstream processing.

Downstream processing

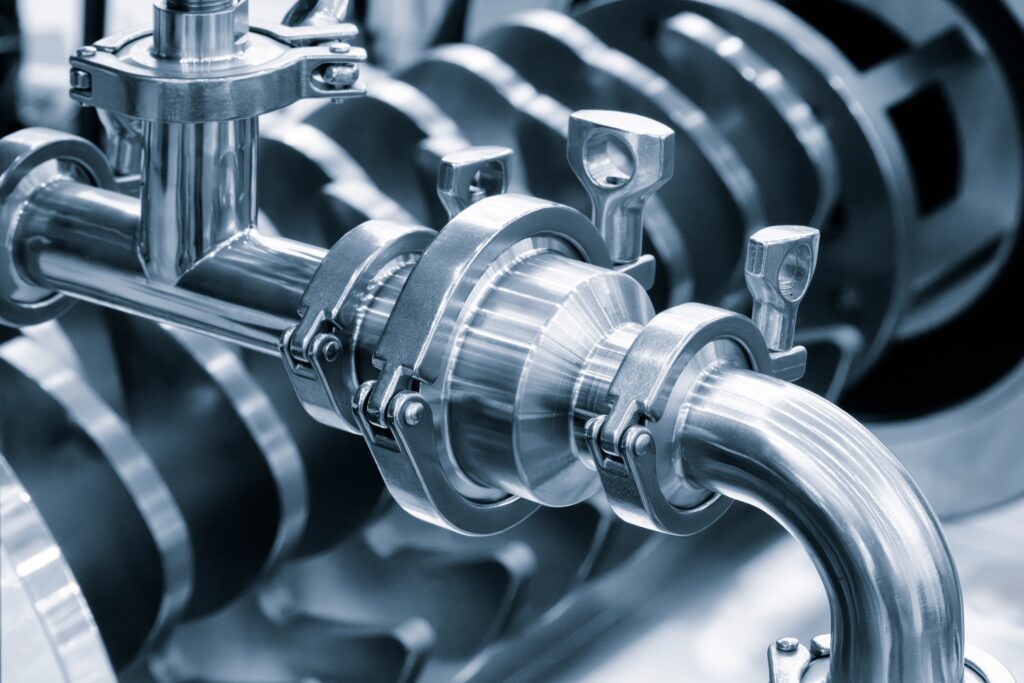

Downstream bioprocessing in biopharmaceutical manufacturing is centred around the recovery and purification of the upstream bioproduct and consists of harvesting and purification stages. The goal is to make the product between 98% to 100% pure, ready for distribution.

For further information about biopharmaceutical bioprocessing, take a look at our Bioprocessing of New Medicines blog.

Bioprocessing in the food industry

Using bioprocessing methods to produce food products from living organisms isn’t new – it’s been harnessed for thousands of years to produce some of the foods and drinks we’ve come to love, such as cheese, bread, beer and wine, among others.

The most widely used bioprocessing method is fermentation, which produces consumables on an industrial scale with modern technology and equipment. This bioprocess uses yeast or bacteria to convert complex compounds in food to produce organic acids or alcohol.

In addition to creating new foods, fermentation can also be used to preserve food products and enhance their properties, such as flavour and texture.

Bioprocessing is still utilised within the modern food industry for other useful reasons, too:

- Reducing carbon emissions to become a greener company – using the bioprocessing process to make foods requires less energy when compared to other creation methods, such as heating at high temperatures.

- Saving energy costs – by utilising less energy to produce desired products, food production companies can lower their total production cost.

Bioprocessing in the fuel industry

Bioprocessing techniques are becoming increasingly popular within the fuel and energy industry to produce fuel blends or next-generation biofuels as a replacement for fossil fuels, such as hydrocarbon petroleum.

Evolving technologies in the field have enabled scientists to make use of the organic properties of biomasses such as algae and plants to create cleaner alternative fuels. This offers ecological benefits by reducing carbon emissions, in addition to financial advantages for biofuel manufacturers thanks to the affordability of abundant natural sources.

Bioprocessing is used to convert organic materials into biofuels and may include revolutionary methods such as pyrolysis, gasification and hydrothermal liquefaction.

During these processes, separations recover the created beneficial products whilst removing any impurities.

Bioprocessing in the chemical industry

Living matter can be adapted using biomanufacturing processes to produce desirable chemicals as an alternative to petroleum-based ones.

Bioprocesses in biochemical production involve processing raw materials in bioreactors or fermentors, followed by a separation and purification stage to retrieve and enhance the advantageous chemical products.

Such eco-friendly chemicals may include biofertilisers, biopesticides, microbial oils and bioethanol.

Why choose ALLpaQ containers?

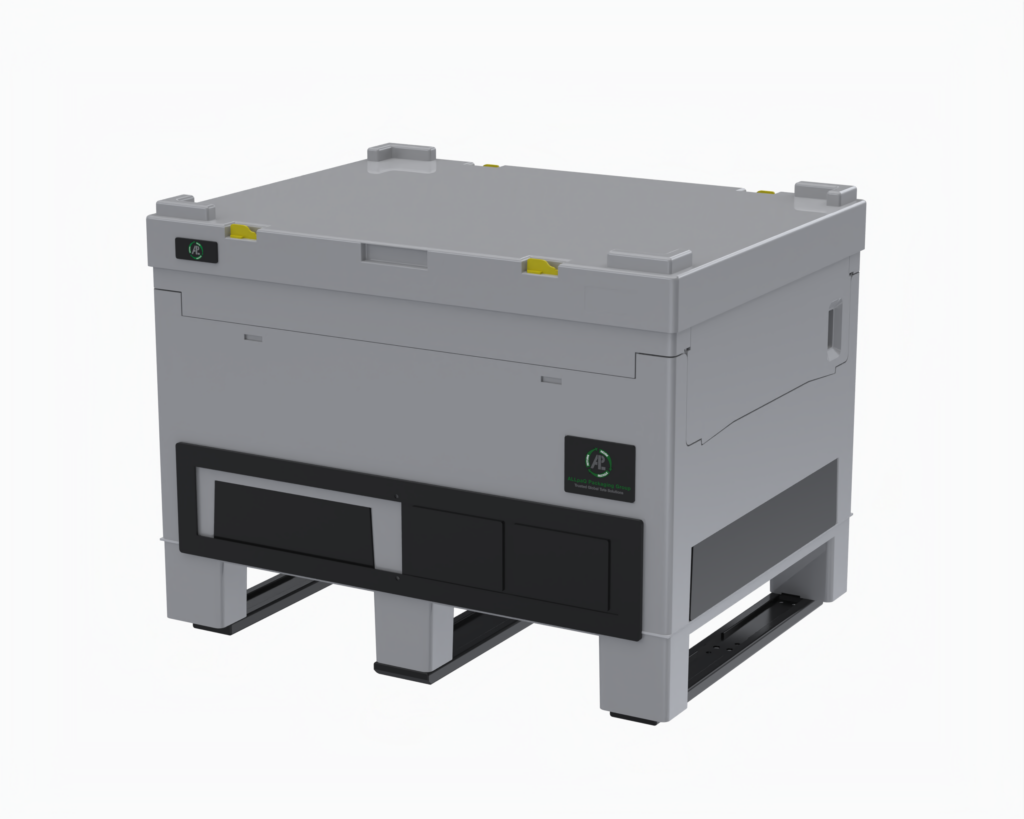

Most bioprocessing applications require efficient liquid storage and management systems to house single-use 2D bags and keep laboratory operations running safely and seamlessly.

Bioprocessing containers are used across an array of industries, most commonly in the pharmaceutical sector during medical research and new medicine development.

With a polyethene bioprocess container system, you can store all the essential fluids for your needs, including culture mediums, buffering solutions, chromatography feed, bioreactor feed and fraction collection.

As an alternative to single-use containers made from flexible film, we supply long-lasting and reusable hard plastic systems that are built to last.

The benefits of ALLpaQ bioprocess containers are substantial:

- Customisable bioprocess containers for distinct applications

- Reduced expenditure on repeat orders of single-use containers

- Rigorous protection against physical damage during fluid transit

- Elimination of bacterial growth and potential solution contamination

- Foldable and ergonomic design for efficient warehouse storage

Speak to the ALLpaQ team today

If you’d like to know more about our revolutionary bioprocess containers, or require further information regarding a custom bioprocess container for your company, our helpful team are on hand to help.

Simply call us on 0147 280 0373 or email us at enquiries@allpaq.com and we’ll be in touch.

Author

Niamh Allen

As a dedicated and detail-oriented Marketing Assistant, Niamh brings a strong passion for creativity and analytics to the marketing team.