Fluid handling in the biopharmaceutical sector works when people work together. This is a plan to reward hard work, share prosperity and build a better biopharmaceutical sector.

Making fluid handling better

The ALLpaQ Party Manifesto 2015

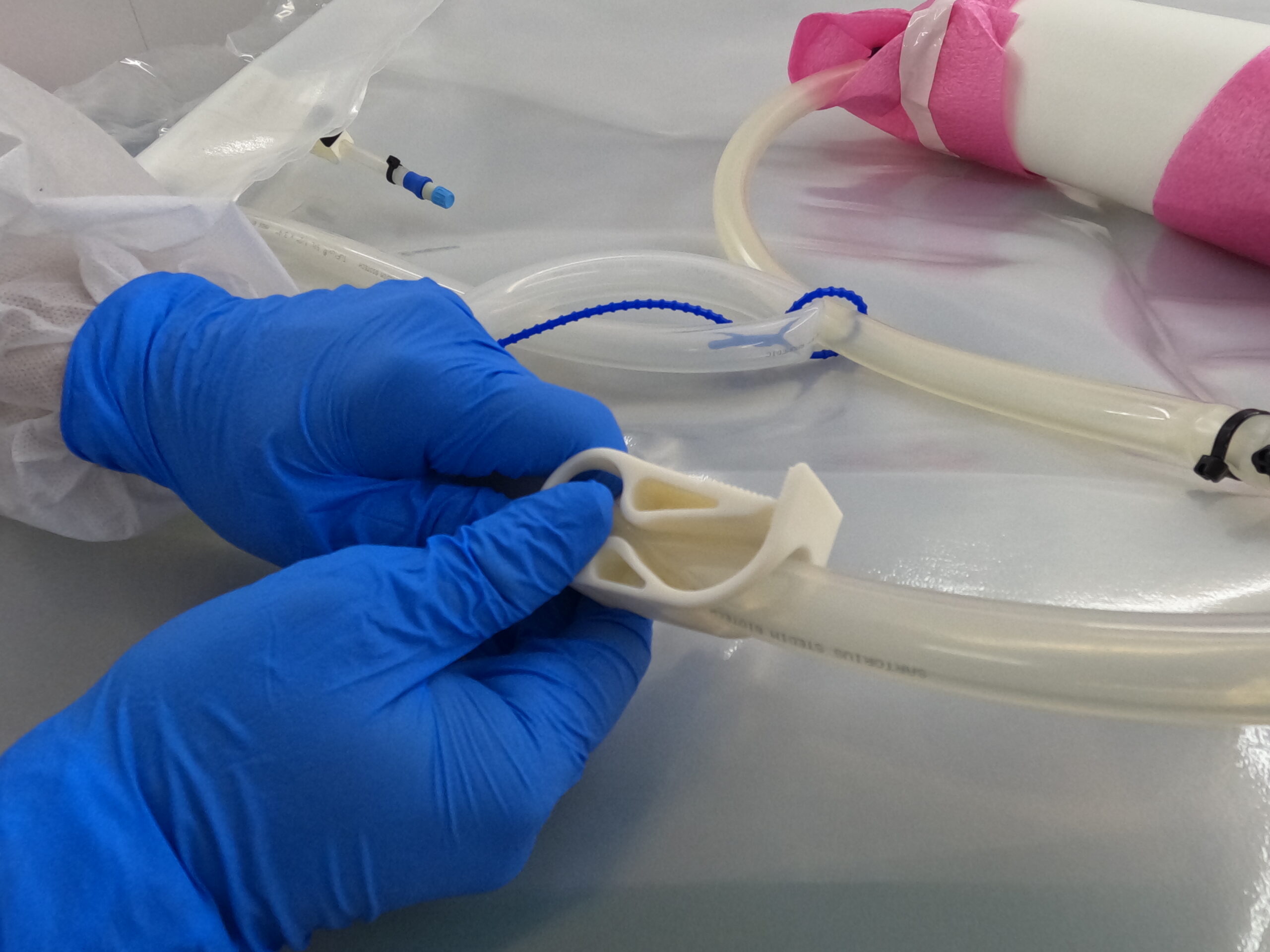

To vote for plastic or steel bioprocess containment? This is the question biopharmaceutical managers are asking when storing and shipping valuable media. With the general election 2015 on the horizon, plastic versus steel containment is indeed the polarising issue of the day.

Now, chances are you’ve previously voted for the steel solution. This is understandable. Steel, after all, boasts a history dipped in prestige. “It lasts forever, doesn’t rust and is unbreakable,” chest thumping politicians have long pronounced from the soapbox.

Yet these words never crystallized, the policies of the Steel Party instead weighing heavy on the economy of the biopharmaceutical sector.

“What about space, storage, transport, hygiene and manual handling issues?” you ask.

We hear you. These are the daily realities you face on the ground.

Our manifesto is therefore forged in the fires of 7 core pledges which, if implemented, will change the socioeconomic fabric of your business.

Together, we’ll make your vote count.

7 reasons to vote for plastic bioprocess containment

So why switch from plastic to steel? The argument is quite simple really. ALLpaQ plastic bioprocess containers enhance the sustainability and profitability of your business.

Embrace the move to plastic and welcome an array of operational and commercial benefits.

Check out the facts:

Manifesto pledge #1: collapsible and stackable

Fabricating in plastic means our containers can be easily collapsed and stacked, allowing you to maximize your warehousing floorspace. This also presents space and cost utilisation benefits when in shipment.

Manifesto pledge #2: operator handling

Unlike the weighty steel equivalent, our bioprocess containers are lightweight and collapsible. This makes manual handling so much easier, allowing you to align with the rigours of health and safety requirements.

Manifesto pledge #3: foldable

ALLpaQ containers can be folded to save space in return shipment. Plastic is also lighter than steel, generating a reduction in shipping charges.

Manifesto pledge #4: reusable

ALLpaQ bioprocess containers can be used time and time again and, in the event of damage, individual panels can be removed and replaced. This adds to the lifespan of your fleet, enhancing sustainability and your bottom line.

Manifesto pledge #5: recyclable

By choosing plastic over the steel alternative, you’ll add to the sustainability of your business. At ALLpaQ, we are committed to a sustainable future through recycling plastic bioprocess containers.

Manifesto pledge #6: hygiene

ALLpaQ products offer better spillage control and can be easily and quickly jet washed. If needed, individual panels can also be removed for cleaning.

Manifesto pledge #7: cost effective

Plastic bioprocess containers are more economical, user friendly and easy to maintain – all healthy for your company’s commercial and operational goals.

How can I cast my vote?

Make contact to cast your vote for all-plastic bioprocess containers.

Vote for a better tomorrow today.

TAGS:

bioprocess containment, plastic versus steel,

SHARE:

Author

Phill Allen

Managing Director

Phill is an innovative thinker particularly in fluid management. His expertise lies in ensuring the seamless flow of pharmaceutical liquid logistics, whether it's optimising current processes or pioneering new approaches.