In the biopharmaceutical space the phrase “single-use” has sounded as of late with more frequency than “coffee please”. From late-stage clinical trials to commercial supply, single-use has become a common denominator.

Actions, of course, speak louder than words. And so it is that increasing numbers of manufacturing facilities, parts and products suppliers are designing bioprocessing technology to be single-use compatible.

The move to single-use technology is more than a fad. It’s a trending. In the global biopharmaceutical space, some experts predict single-use to increase at a compound annual growth rate of 9.4% from 2014 to 2020, hitting the heights of $278 billion.

With so many benefits, it’s almost ironic that it’s called single-use. So, with this in mind, here’s 6 ways in which single-use technology can enhance the bioprocessing supply chain.

Single-use 1: Get productive

Single-use technologies deliver an array of benefits direct to workers at the coalface of your biopharmaceutical business. Optimised work processes also deliver benefits to your bottom line.

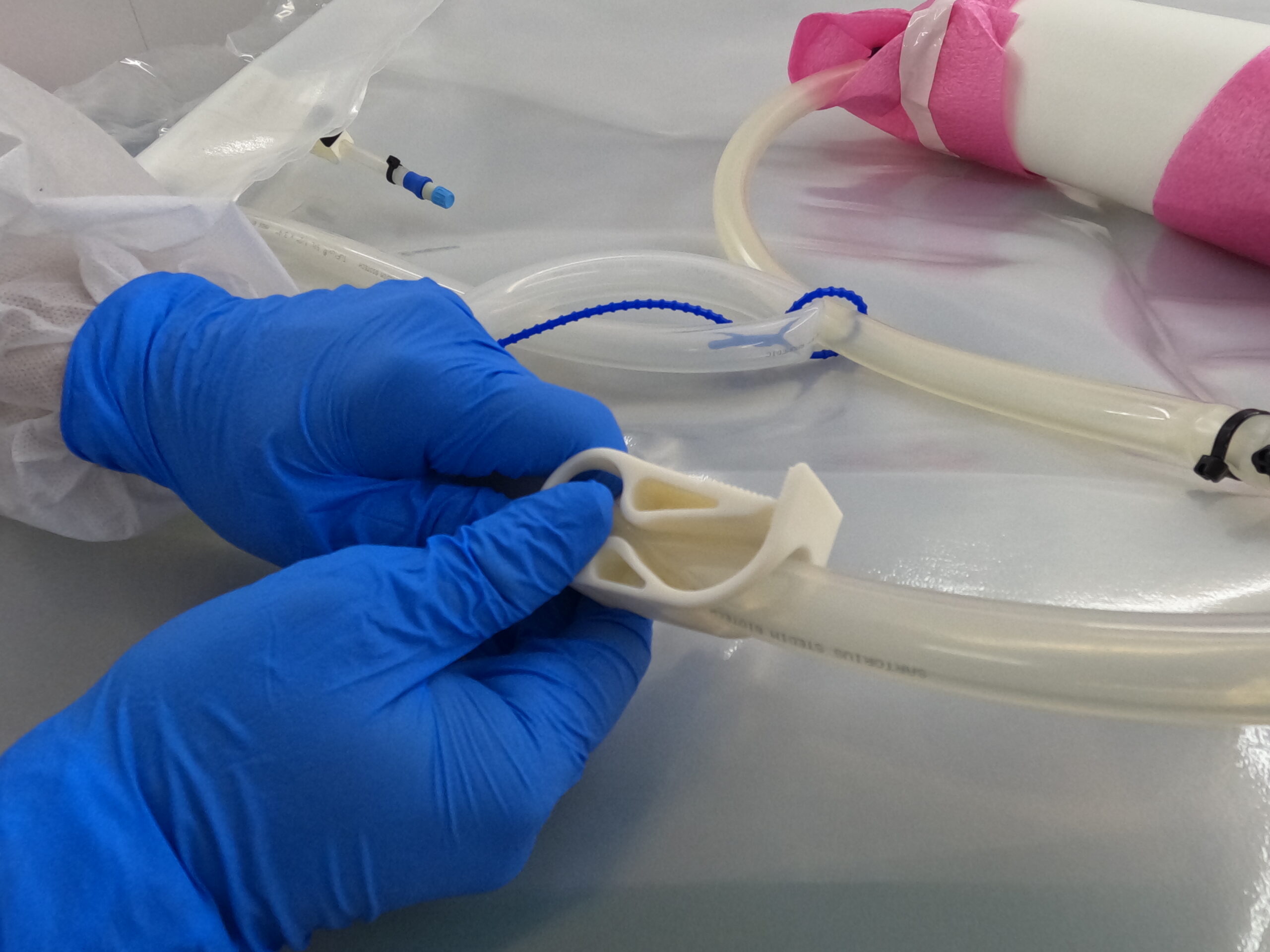

Consider the time and resource expended in cleaning and sanitising a traditional stainless steel bioprocess containment system. Flip that coin, and disposable systems can be changed out in a fraction of the time.

Single-use 2: Cut costs

Like socks, reusable parts need cleaning. Single-use, on the other hand, removes the costs of the products and tools used in the cleaning process. This also reduces storage space, energy consumption and, finally, costs.

Single-use 3: Manufacturing process improvements

In biopharmaceutical manufacturing, time is of the essence. Single-use systems can create businesses more additional time than a watch maker.

How? Because single-use systems can achieve significant reductions in labour. The technology also generates faster batch-turnaround and product changeover.

Single-use 4: Quality control

Single-use brings greater accuracy to quality control. The technology reduces the

risks of cross and bioburden contamination. Likewise, it helps businesses align with cleaning validation, satisfying the requirements of regulatory agencies.

TAGS:

Biopharmaceutical, Bioprocessing, Single-use,

SHARE:

Author

Phill Allen

Managing Director

Phill is an innovative thinker particularly in fluid management. His expertise lies in ensuring the seamless flow of pharmaceutical liquid logistics, whether it's optimising current processes or pioneering new approaches.